CONTACT DETAILS

National Tel : 0861040506

International Tel : +27117925226

Cellular : 0832514312 / +27832514312

info@liftlash.co.za

PAGE NAVIGATION

LIFTING - Caldwell Main Catalogue

Section D

UNIVAC®

Vacuum Lifters

Nominal Applications

Narrow Applications

Wide Applications

Vacuum Upenders

Mechanical Vacuum Lifter

Specialty Lifters

Uniclamp™ Hold

Down Clamps

Index to Vacuum Lifters

About Vacuum Lifters

Model Number Breakdown & Options D.4

Power-Pac D.5

Nominal Applications

Single Pad Unit–Model A D.6 - D.7

Narrow Applications

Twin Pad Unit–Model B D.8 - D.9

Quad Pad Unit–Model C D.10 - D.11

Wide Applications

Twin Crossarms–Model D D.12 - D.13

Triple Crossarms–Model E D.14 - D.15

Quad Crossarms–Model F D.16 - D.17

Vacuum Upenders

Upender Twin & Quad Crossarm–Model U D.18 - D.19

Upender/Downender–Model T D.20 - D.21

Mechanical Vacuum Lifters

Mechanical Vacuum Lifters D.22 - D.23

Specialty Applications

Specialty Vacuum Applications D.24 - D.25

Side Grab Manipulator D.26

Variable Size Sheet Lifter D.26

Univac® Application Evaluation D.27

Uniclamp™

Uniclamp™–General D.28

Uniclamp™–Lightweight D.29

Uniclamp™–Middleweight D.30

Uniclamp™–Heavyweight D.31

Uniclamp™ Applications D.32

Parts, Care & Use

Vacuum Parts D.33 - D.34

Care & Use D.35

Quality & Engineering

The Caldwell Group has been manufacturing lifting equipment since 1954. It is our goal to manufacture high quality, long lasting lifting products that will safely increase productivity and reduce operating costs.

UNIVAC® Vacuum Lifters are designed for efficient, one-person operation in lifts of semi-porous and non-porous material. Unlike magnets or edge grabs, vacuum units will not mark or scratch material surfaces or edges. Additionally, vacuum lifters can easily lift nonferrous metals and thin sheets (under ¼”).

Benefits your company will receive with UNIVAC® Vacuum Lifters:

• Increase productivity, reducing cost.

• Versatile handling of most materials.

• One person operation.

• Improve storage space.

• Eliminate material damage.

• Provide a low maintenance lifter.

• Precision handling made easier.

• Durable for long lasting service.

All UNIVAC® Lifters Have:

• Identification nameplate as required by ASME.

• Rated capacities and product safety labels.

Industry Standards

The American Society of Mechanical Engineers (ASME) has developed standards that apply specifically to these types of devices. ASME B30.20 provides detailed information on the classifications, marking, construction, installation, inspection, testing, maintenance and operation of below the hook lifting devices. ASME BTH-1 provides detailed information on the design criteria of below the hook lifting devices.

These standards serve as a guide to government authorities, manufacturers, purchasers

and users of lifting devices. For a summary of these standards, please see pages 8-10 in

the front of this catalogue.

UNIVAC® Vacuum Lifters adhere to the highest quality standards in the industry and

all units conform to ASME standards. All UNIVAC® Vacuum Lifters are designed to a structural safety factor of 3:1 and a vacuum pad safety factor of 2:1.

Caldwell Service

We offer solutions that will increase the productivity and effectiveness of your lifter, while ensuring the safety, reliability, and compliance of your equipment. Our services include: training & maintenance, inspection, repairs and modernizations.

DISCLAIMER:

All product designs are subject to change without notice. Products pictured in this catalogue are a representation of a specific design. The product you purchase will be designed for your specific application and may not look exactly like the picture in this catalogue.

Model Information

Model Number Breakdown & Options

BREAKDOWN OF MODEL NUMBER 7 PART CODE

OPTIONS FOR STANDARD MODELS:

Description Code

• Parking Stand - built-in storage stands. CODE - P

• Side Handle (one side) - electric units except Model A. CODE - HS

• Fork Pockets. CODE - FP

• Low Vacuum Warning System - electric only. CODE - W

• Silicone pads for temperatures - over 200°F to 600°F (Replaces neoprene pads). CODE - S

• Transformers for AC voltage - other than 115 volt. CODE - T

• Custom Pendant - controls all crane and vacuum lifter functions. CODE - Z

• Special vacuum power units. CODE - CONSULT FACTORY

- Battery (Univac® 330 only)

- Gas

- Propane

ADD CODE AS SUFFIX TO MODEL NUMBER

EXAMPLE: DE12V85D3-P to add parking stand

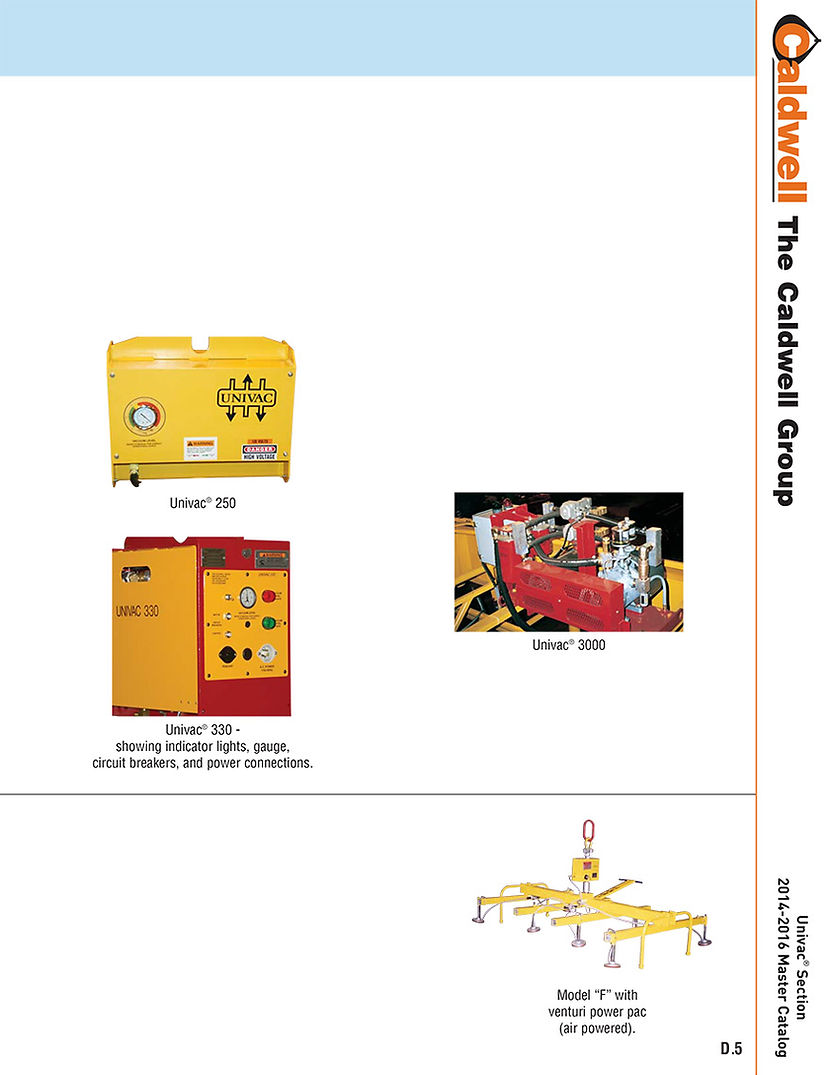

Power-Pac - The Heart of The System

VACUUM POWER-PAC, is in a self contained cabinet that mounts to the top of the load beam and is powered by either electric motor or shop air (venturi unit).

ELECTRIC UNITS FEATURE:

• Vacuum reserve tank - maintains holding power temporarily in the event of a power failure.

• Two button pendant control with 10' cord and plug to user power supply (except Univac® 250).

• Power cabinet has removable covers for easy access.

• Red/green indicator lights (except Univac® 250).

• Circuit breakers for electrical overload protection.

Electric Motor Driven Pumps Available

UNIVAC® - 250 vacuum generator - 4 C.F.M., dry piston pump, power supply - 115V-1PH-60HZ.

UNIVAC® - 330 vacuum generator - 1/4 H.P., non-lubricated, 4 C.F.M., rotary vane pump, power supply - 115V-1PH-60HZ and optional battery.

UNIVAC® - 1500 vacuum generator - 1-1/2 H.P., non-lubricated, 21 C.F.M., rotary vane pump, power supply - 230/460V-3PH-60HZ.

UNIVAC® - 3000 vacuum generator - 5 H.P., non-lubricated, 55 C.F.M., rotary vane pump, power supply - 230/460V-3PH-60HZ, 230VDC.

SHOP AIR (VENTURI) UNITS FEATURE:

• Visual indicator gauges.

• Check valve for positive holding in case of air hose or compressor failure.

• No electric service required.

Shop Air (venturi unit)

V-40 vacuum generator - operates on approximately 50 PSI shop air.

Nominal Surface Area Applications

Model A - Single Pad - Standard Duty

For lightweight material with small square shaped surface. Neither the width or the length should exceed 5 times the pad diameter (see specifications below for pad diameter).

PRODUCT FEATURES:

• Ball mounted vacuum pads.

• Brass fittings.

• Push lock hose (designed for 250 psi).

• Muffler/filter is spin on type for easy change out.

Nominal Surface Area Applications

Model A - Single Pad - Heavy Duty

Single pad units with large or small capacities are used when surface area is at a minimum.

Univac® 330 unit - side view showing vacuum indicator lights and power/control connections.

Single pad unit shown with a 10" diameter sponge pad for lifting semi-porous material.

Narrow Applications

Model B - Twin Pad Load Beam - Standard Duty

For lifting smaller rectangular shaped material. Width should not exceed 5 times the pad diameter (see specifications below for pad diameter).

PRODUCT FEATURES:

• Ball mounted vacuum pads.

• Brass fittings.

• Push lock hose (designed for 250 psi).

• Slide valves allow for manual isolation of vacuum pads.

• Muffler/filter is spin on type for easy change out.

Narrow Applications

Model B - Twin Pad Load Beam - Heavy Duty

For lifting smaller rectangular shaped material. Width should not exceed 5 times the pad diameter (see specifications below for pad diameter).

Narrow Applications

Model C - Load Beam with 4 Inline Pads - Standard Duty

For lifting long, narrow sized material. Width should not exceed 5 times the pad diameter (see specifications below for pad diameter).

PRODUCT FEATURES:

• Ball mounted vacuum pads.

• Brass fittings.

• Push lock hose (designed for 250 psi).

• Slide valves allow for manual isolation of vacuum pads.

• Muffler/filter is spin on type for easy change out.

Narrow Applications

Model C - Load Beam with 4 Inline Pads - Heavy Duty

For lifting long, narrow sized material. Width should not exceed 5 times the pad diameter (see specifications below for pad diameter).

In line units to handle long narrow material.

Individual pads can be isolated from the system with the standard manual slide valves.

Wide Applications

Model D - Twin Crossarms with 4 Pads - Standard Duty

For lifting wide or thin material. The crossarms make the load easier to balance.

PRODUCT FEATURES:

• Ball mounted vacuum pads.

• Brass fittings.

• Push lock hose (designed for 250 psi).

• Slide valves allow for manual isolation of vacuum pads.

• Muffler/filter is spin on type for easy change out.

Model DE6S6-6-D3 shown

Univac® 250 for capacities

less than 1,240 pounds

Model DE16V8-6-D3 shown

Univac® 250 for capacities

of 1,240 to 2400 pounds

Unit shown with optional fork pockets.

Wide Applications

Model D - Twin Crossarms with 4 Pads - Heavy Duty

For lifting wide or thin material. Crossarms allow for extra stability for wider material and reduce amount of

deflection for thinner material.

Wide Applications

Model E - Triple Crossarms with 6 Pads - Standard Duty

For lifting long, wide, and moderate weight material or to provide increased support of thin material.

PRODUCT FEATURES:

• Ball mounted vacuum pads.

• Brass fittings.

• Push lock hose (designed for 250 psi).

• Slide valves allow for manual isolation of vacuum pads.

• Muffler/filter is spin on type for easy change out.

Wide Applications

Model E - Triple Crossarms with 6 Pads - Heavy Duty

For lifting long, wide, and moderate weight material or to provide increased support of thin material.

Manual slide valves shut off individual crossarms allowing the operator to easily customize the lifter to match the load.

Above lifter utilizing a parking stand (Option P), side handle (Option HS), and transformer (Option T).

Model EE80V16-16-T4 shown with optional twin bails

Wide Applications

Model F - Quad Crossarms with 8 Pads - Standard Duty

PRODUCT FEATURES - ECONOMY & INDUSTRIAL:

• Ball mounted vacuum pads.

• Brass fittings.

• Push lock hose (designed for 250 psi).

• Slide valves allow for manual isolation of vacuum pads.

• Muffler/filter is spin on type for easy change out.

For lifting longer, wider and heavier weight material or to provide increased support of thin material.

Wide Applications

Model F - Quad Crossarms with 8 Pads - Heavy Duty

For lifting longer, wider and heavier weight material or to provide increased support of thin material.

Sponge vacuum pads used to handle rough material such as tread plate.

Crossarms are adjustable along load beam; and pads can be adjusted along the crossarms, providing maximum flexibility

Vacuum Upenders

Model U - 90º Tilt Upender/Downender - Standard Duty

PRODUCT FEATURES:

• Standard 110V plug-in style power supply for easy installation.

• Vacuum reservoir maintains load in the event of power loss.

• Fully adjustable to handle varying lengths/widths of material.

• Linear actuator provides smooth, continuous tilting.

• Color-coded vacuum level indicator gauge is easy to read.

• Adjustable guide handle for ergonomic operation.

• Non-marking neoprene vacuum pads protect the load from damage.

Caldwell’s new Vacuum Upender can be used to handle numerous non-porous materials. Eliminate the additional work pieces and manpower required to properly position your product.

Twin Crossarm Models have four pads and are available with main beam lengths of 4', 6', or 8' and crossarm lengths of 3', 4' or 5'.

Quad Crossarm Models have eight pads and are available with main beam lengths of 6', 8', or 10' and crossarm lengths of 3', 4' or 5'.

Twin Crossarm

Quad Crossarm

Vacuum Upenders

Model U - 90º Tilt Upender/Downender - Standard Duty

Vacuum Upenders

Model T - 90° Tilt Upender/Downender - Heavy Duty

PRODUCT FEATURES:

• Linear actuator provides smooth continuous tilting.

• Electric powered only.

• Mould on pads are used for glass applications

Lifting and rotation to 90° for assembly area, vertical storage, inspection, and glass handling applications.

Vacuum Upenders

Model T - 90° Tilt Upender/Downender - Heavy Duty

Ideal for material that needs to be tilted up or down for inspection or placement into shipping containers.

Steel plate shown horizontal

Electric upenders allow the operator to position the plate anywhere from 0 to 90 degrees.

Electric upender shown at 90° position

Electric upender shown horizontal

Mechanical Vacuum Lifters

Mechanical Vacuum Lifter

PRODUCT FEATURES:

• No outside power source is required.

• Color-coded vacuum indicator rods alert the operator of vacuum level.

GREEN = Safe to lift with additional vacuum available.

YELLOW = Minimum vacuum remaining, begin to set load down.

RED = Hazardous condition.

• Auto cycling valve provides a hands-free attach and release function.

• Large lifting bail accommodates a wide range of hook sizes.

• The Caldwell Mechanical Vacuum Lifter has very few moving parts that will need attention from the maintenance department.

• Standard sizes shown, please contact factory for additional capacities and configurations.

The patented, revolutionary design of our vacuum generator requires no electrical or air line connections, just hang it on your hook and go! This is an economical solution for a wide range of applications where bringing power to the lifter is not practical or feasible—even the warning system requires no power. This virtually maintenance free design conforms to ASME standards

Mechanical Vacuum Lifters

Specialty Applications

Specialty Vacuum Applications

Heavy duty vacuum lifter with vacuum pads mounted on wheeled trolleys for ease of pad adjustment

Lifting and rotation to 90° for assembly area, vertical storage, inspection, and glass handling applications.

Lifting and rotation to 90° for assembly area, vertical storage, inspection, and glass handling applications.

Lifting and rotation to 90° for assembly area, vertical storage, inspection, and glass handling applications.

Specialty Applications

Specialty Vacuum Applications

Submersible vacuum lifter can pick and place aircraft aluminum plate from under water in an ultrasonic testing tank.

Custom 33" square pad vacuum lifter used on a shear line.

Bridge truss type unit used by a major aluminum producer to load finished aircraft wing skins into shipping container

Radio controlled, 20,000 pound capacity unit for loading a burn table for a major steel producer

Auto-attach/release bail on this vacuum lifter allows for hands-free operation. Available as 6,000 pounds single pad or 12,000 pound dual pad units, these 33"

square pads are designed for handling material in steel and aluminum mills.

Specialty Applications

Side Grab Manipulator Vacuum Lifter

PRODUCT FEATURES:

• Electric or venturi power available.

• Manual or motorized product rotation.

• Adjustable for various load widths.

• Simple push button controls

Designed to manipulate 180° for production, inspection and assembly applications.

Variable Size Sheet Vacuum Lifter

PRODUCT FEATURES:

• Standard UNIVAC® electric vacuum Power-Pac.

• Standard options see page D.4. (contact us for availability)

Designed to handle the wide range of steel plates typical in a shearing operation.

Application Evaluation

For a price quote on your specific application, please complete the above form and contact us

Uniclamp™

Uniclamp™ Welding Hold Down Clamp

This conventional setup can take up to two hours to

complete. The process includes welding lugs, dogs and bridges in place - positioning awkward and heavy equipment - then removing these setups and cleaning up the attachment points.

WHAT IT DOES:

UNICLAMP™ ELIMINATES THE GAP BETWEEN THE PLATE AND THE STIFFENER!

The Uniclamp™ takes less than 30 seconds to set up - increasing productivity, safety and quality.

HOW IT WORKS:

The simple connection of a standard plant-supplied compressed air line and the flick of a switch allows the clamp’s built-in, high speed generator to create a powerful vacuum, permitting the vacuum pads to immediately attach themselves directly to the work surface. The clamp’s manual screw or hydraulic ram can then be operated to instantly secure the proper alignment of parts.

UNICLAMPS™ will meet your clamping requirements without the tedious, time consuming and sometimes dangerous paraphernalia associated with traditional methods of fabrication assembly techniques. NO MORE LUGS, DOGS, BRIDGES, WEDGES, CHAINS, JACKS, C-CLAMPS, TACK WELDS, OR REGRINDING REQUIRED!

UNICLAMPS™ Are Powered by Compressed Air and Leave No Marks!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

Uniclamp™

The Lightweights…

The WHD-1 and WHD-2 UNICLAMPS™ feature capacities up to 1,200 lbs with clamp weights not exceeding 18 lbs! Features include round or rectangular vacuum pads, varying headframe widths, and varying height under the ram to suit special requirements.

WHD-1 and WHD-2 models are constructed of a high-strength aluminum bringing lightweight portability to workpiece positioning and clamping.

The UNICLAMPS™ have proved to be invaluable in transportation industry applications. These easy to position clamps are ideally suited for sheet and light plate fabrication. Lightweight UNICLAMPS™ are used to secure “skin” materials to ribbed structures at aircraft, aerospace, bus, trailer, and truck manufacturing facilities.

UNICLAMPS™ Disassemble in Seconds Without Tools!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

Uniclamp™

The Middleweights…

The WHD-18 and WHD-24 UNICLAMP™ features include round or rectangular vacuum pads, varying headframe widths, and varying height under the ram to suit special requirements.

Like their smaller counterparts, the UNICLAMP™ Models WHD-18, WHD-24, WHD-32 and WHD-40 are constructed of high-strength aluminum affording these clamps the identical advantage of reduced weight for heavier duty positioning and clamping requirements.

The clamp models are used extensively in aircraft, ship building, bridge construction, tank manufacturing and the steel fabrication industry. They excel whenever larger assemblies need to be drawn into alignment or held in position for a welding process.

The WHD-32 and WHD-40 are available with round vacuum pads, varying headframe widths, and varying height under the ram to suit special requirements. The WHD-40 is available with rectangular vacuum pads.

UNICLAMPS™ Disassemble in Seconds Without Tools!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

Uniclamp™

The Heavyweights…

The WHD-60, WHD-80, and WHD-100 welding and fabrication clamps, boast holding force up to 10,000 lbs. with a venturi vacuum generator and a hydraulic powered ram as standard features. Vacuum pads in round, rectangular, or square are available to suit custom requirements.

UNICLAMP™ Steel Constructed Models WHD-60, WHD-80 and WHD-100 answer industry’s heaviest application requirements.

Used in ship building, heavy plate fabrication, plant construction, bridge building, and large tank fabrication, these clamps bring incredible amounts of clamping power to bear on the largest of fabrication application requirements. These easy-to-use, portable, high-speed clamps draw oversize materials into position for welding, assembly, or alignment procedures.

UNICLAMPS™ Disassemble in Seconds Without Tools!

NOTE: UNICLAMPS™ ARE NOT DESIGNED FOR LIFTING PURPOSES.

Uniclamp™

Uniclamp™ Applications

Whether work surfaces are angled, inclined, right angles, convex or concave, UNICLAMPS™ provide the best solution for your positioning and clamping needs.

Special Sizes and Designs Are Available for All UNICLAMPS™

GANG CLAMPS FOR LONG LOADS

OVERHEAD APPLICATION

CURVED SECTION WELDING

VERTICAL CLAMPING OF BEAM

SURFACE WELDING STIFFENER

ALIGNING CURVED SURFACES

Vacuum Lifter Parts

Replacement Parts & Repairs

Many commonly needed parts are in stock, ready for immediate delivery. Other special components are produced on order. Caldwell gives priority to replacement parts to insure minimum downtime.

Repairs

Vacuum lifting products, of many brands, can be sent to Caldwell for repair. Units are completely disassembled, inspected, worn parts replaced, reassembled and tested. You get a “like new” vacuum lifter at considerable savings over the cost of a new unit.

Vacuum Lifter Parts

UNIVAC® Vacuum Lifter Sample Parts Schematic

This is a sample vacuum lifter parts schematic, please refer to your instruction manual for specific information regarding your Univac® Vacuum Lifter.

Care & Use

INSTALLATION

Vacuum Lifters shall be assembled and installed in accordance with the manufacturer’s instructions, unless other specific arrangements have been approved in writing by manufacturer. When lifter/auxiliary power supply is required, user inspection shall ensure that the power source complies with ANSI/NFPA 70, National Electrical Code and shall include a power disconnect switch as required in accordance with ANSI/NFPA 70 based on the lifters requirements. If electrical connections are made, the power supply and corresponding power disconnects shall be connected to the line side (power supply side) of the crane disconnect or to an independent circuit as specified in the manufacturer’s operating instructions.

Check for correct rotation of all pumps and power units, lubrication of moving parts, and filling of reservoirs, all in accordance with manufacturer’s instructions.

OPERATOR TRAINING

Lifters shall be operated in accordance with manufacturer’s instruction manual, and by personnel who have received instructions described in the “Operating Practices” section of these guidelines. Training shall also include instruction regarding:

1. Details of the lifting cycle.

2. Application of the lifter to the load including (according to the manufacturer’s instructions) adjustments to the lifter, if any, to adapt it to various sizes and kinds of loads.

3. Instruction in any special operations or precautions that may be required.

4. Recognition of proper load configuration. For example, preferred

operation requires an orderly pattern of stacking.

5. Before assuming responsibility for using the lifter, an operator shall

demonstrate his understanding of the lifting procedure to the instructor. The instructor should record notes of operator’s demonstrated ability.

INSPECTION

Defects to look for include but are not limited to:

1. Structural deformation.

2. Cracks in the structural frame, welds, hoist hook attachment points,

mechanically operating parts, and attached slings, clevises and hooks.

3. Wear of hoist hooking points, load supporting clevises, pins, slings,

linkages and mechanical parts.

4. Missing nameplates and markings. Contact Caldwell for replacements.

Daily: Perform filter and muffler check. Perform a preliminary test lift of several inches.

Weekly: Check seal rings, hoses and fittings. Check for loose bolts and nuts, as well as for structural damage. Test vacuum gauge reading. Test vacuum switch setting.

Quarterly: Clean vacuum pump.

Check vacuum gauge.

Check Red and Green indicator lights.

MAINTENANCE AND REPAIRS

1. A preventive maintenance program should be established for each

lifter by a qualified person based on recommendations made by its

manufacturer.

2. A qualified person should have responsibility for repairs. Dated records and details of repairs and parts replacement should be carefully maintained by a qualified person, and copies kept in your

possession.

3. Replacement parts shall be at least equivalent to the original

manufacturer’s specifications.

Reference from: UNIVAC® operation maintenance & parts manual (included with each order).

OPERATING PRACTICES

DO’S

1. The operator shall receive, read and understand the manufacturer’s

instruction manual.

2. The operator shall watch carefully that the lifter is performing properly during the lifting procedure.

3. The operator shall know the standard crane hand signals.

4. The operator shall only respond to signals from an appointed person. However, stop signals from anyone shall be obeyed.

5. The operator shall notify a designated person when he considers a

load to be unsafe.

6. The operator shall inspect the lifter before using. Any defect observed shall be examined by a qualified person to determine if it

is a hazard.

DON’TS

1. The operator shall not operate a malfunctioning lifter or one with an “out of service” tag attached.

2. The operator shall not use the lifter for any purpose(s) other than

those designated by the manufacturer’s instruction manual.

3. The operator shall not use a lifter when the capacity, weight or product safety labels are missing or are no longer legible.

4. No one shall make alterations or modifications to lifters without consulting the manufacturer.

5. No one shall obscure or paint over the manufacturer’s capacity, weight, or product safety labels.

6. Loads shall not be lifted higher than necessary or be left suspended unattended.

7. The lifter shall not lift a load that is not properly balanced for safe lifting.

HANDLING THE LOAD

1. The lifter shall not be loaded in excess of its rated load.

2. Ensure the load can withstand the forces applied by the lifter.

3. The combined weight of the lifter and load shall not exceed the rated load of the crane or hoist.

4. The lifter shall be applied to the load in accordance with the manufacturer’s recommended operating procedure.

5. Lifter ropes and chains shall not be kinked, and multiple part lines

shall not be twisted about each other.

6. The lifter shall not touch obstructions during load movement.

7. The lifter shall not be loaded with loose material that might fall

during movement.

8. The operator or other personnel shall not place themselves or any

part of their bodies beneath suspended loads.

9. The load or lifter shall not be slid on the floor or other surface.

10. The lifter shall not be used for loads for which it is not designed.

11. If suspended loads are moved manually, they shall be pushed,

not pulled.

12. A preliminary lift of a few inches shall be made to establish that the load is stable.

13. All loads shall be accelerated and decelerated smoothly and slowly.

Modifications or repairs performed on your lifting equipment without prior written approval from The Caldwell Group, Inc. voids your warranty. Refer to ASME standards for information regarding the liability of repaired or modified lifters