CONTACT DETAILS

National Tel : 0861040506

International Tel : +27117925226

Cellular : 0832514312 / +27832514312

info@liftlash.co.za

PAGE NAVIGATION

LIFTING - Caldwell Main Catalogue

Section I

CALDWELL®

Slings & Tie Downs

Standard Web Slings

Roundslings

Alloy Chain Slings

Wire Mesh Slings

Wire Rope Slings

Special Application

Web Slings

Cargo Tie Downs

Specialty Lifters

Introduction to Caldwell® Slings & Tie Downs

The Caldwell Group has been manufacturing quality lifting equipment since 1954. It is our goal to manufacture high quality, long lasting products that will safely increase productivity.

Lifts can be large or small; heavy or light; bulky or fragile, applications of lifting slings are truly unlimited. Our synthetic

slings can lift items that require careful handling such as expensive machinery, highly finished parts, and fragile loads.

Our Wire Mesh, Rope and Chain Slings can handle pipe, steel, wood or any item that is not finished.

How To Use This Section

Please take a few moments to read the following pages. The information contained in these pages will help you in selecting the best sling for your application. Our inside sales department is also available to aid in selecting the correct sling for the applications or answer any questions you may have.

Why Caldwell?

Product safety and reliability are important. This is why Caldwell slings meet or exceed current ASME, WSTDA, and OSHA

standards. All Caldwell® Lifting Slings Have:

• Care and use information provided with every sling.

• Registered Tags.

• Product Safety Labels.

Caldwell Standard Quality

Caldwell slings follow specific design criteria as required by ASME. See the specific sling type within this section for details

on that specific type of sling. If you would like your sling proof tested and a test certificate issued, please specify at the time of order (there is a nominal charge).

Standard Web Slings - These lightweight and easy to use slings are best used in situations when the loads need to be protected from damage, or a flexible sling is required for easy rigging. Type 1 through 6, including Unilink®.

Special Application Slings - Each sling is designed for a specific application. Cargo Slings, Bridle Slings; Drum Handling, Pipe Lifting Slings, and Wheel Nets.

Roundslings - These lightweight synthetic slings are super flexible to conform to the shape of your load. Double jacket protection increases sling life. Color-coded by capacity for easy identification on the job site.

Wire Rope Slings - The most economical sling per ton of lift. Provides the strength and sturdiness required for lifting those tough loads. Used in industries where heavy loads and rugged conditions exist. Many configurations are available with a variety of end fittings.

Alloy Chain Slings - Superior strength slings, ease of handling and durability. Used in environments having severe lifting conditions such as foundries, steel mills, and heavy machining operations. Chain slings provide the longest sling life in conditions commonly seen in these environments.

Wire Mesh Slings - Widely used in metalworking machine shops and other industries where loads are abrasive, hot or have sharp edges, such as bar stock or plate steel. Mesh slings grip the load firmly without stretching, and the sling width greatly enhances load balancing.

Cargo Tie Downs - Can satisfy just about every cargo securing requirement. High strength webbing is available from 1" to 4" wide with a large assortment of end fittings, tighteners and optional accessories.

Standard Applications

Index to Caldwell® Slings & Tie Downs

Standard Web Slings

Type I, II & Unilink® I.6

Type III & IV I.7

Type V I.8

Type VI I.9

Special Application Web Slings

Bridle I.10 - I.11

Pipe Handling I.12 - I.13

Cargo Type I.14

Wheel Nets I.15

Drum Handling I.16

Web Sling Accessories I.17

Web Sling Care & Use I.18

Roundslings

Roundslings I.19 - I.20

Roundsling Care & Use I.21

Wire Rope Slings

Wire Rope Slings I.22 - I.24

Wire Rope Care & Use I.25

Alloy Chain Slings

Alloy Chain Slings I.26 - I.29

Load Leveling Chain Slings I.30

Alloy Chain Slings Care & Use I.31

Wire Mesh Slings

Wire Mesh Slings I.32

Wire Mesh Care & Use I.33

Cargo Tie Downs

Properties, Care & Use I.34 - I.35

Light Duty I.36 - I.37

Medium Duty I.38 - I.39

Heavy Duty I.40 - I.41

Quality & Engineering

PRODUCT FEATURES

Shock Absorption

The stretching of web slings allows a cushion against sudden shock. When loaded at rated capacity, a nylon sling will stretch 6-8%. Slings will return to normal length when not loaded.

Registered Sling With Tag

Caldwell® Slings have a registered tag in accordance with industry standards indicating:

1. Manufacturer

2. Type Material—nylon or polyester

3. Serial No.

4. Rated Capacities Caldwell® Web Slings are marked to show:

Rated Capacity (RC) by hitch

• Choker (C)

• Vertical (V)

• Basket (B)

5. Length of Sling

Warning Tag

Caldwell® Slings have a warning tag:

Certification Of Web Slings

1. A Caldwell letterhead certification guaranteeing rated capacities and/or adherence to specifications is available upon request at no additional charge.

2. Proof testing services are available upon request (there is a nominal charge).

SLING WEBBING

Web Material — Soft And Flexible

Web slings are made from nylon or polyester lifting yarn that is woven into various widths and thicknesses. Sling webbing has its surface yarns connected from side to side, which not only protects the core yarns, but positions all surface and tensile yarns to work together to support the load.

Webbing Strength

The WSTDA and ASME (standard B30.9) recognizes two strengths of webbing:

1 Heavy Duty —webbing possessing minimum certified tensile strength in accordance with industry standards.

2. Medium Duty —webbing possessing a minimum certified tensile strength in accordance with industry standards.

Warning Core

Colored yarns under the jacket yarn show when the sling is worn or cut through, indicating the sling shall be removed from service and destroyed. Hardware can be retained and reworked if still in acceptable condition.

Chemical Exposure

Many chemicals have an adverse effect on sling material.

Industry Standards That Affect Web Slings:

1. American Society of Mechanical Engineers - ASME B30.9 Standards for Slings.

2. Occupational Safety Health Administration - 1910.184 Standards for Slings.

3. Web Sling and Tie Down Association - Recommended Standard Specification for Synthetic Web Slings.

Standard Web Slings

SLING SELECTION

Select a sling having suitable characteristics for the type of load, hitch and environment to which it will be subjected.

1. Sling Capacity

Determine weight of the load.

2. Sling Type

Select a sling of suitable design for the type of hitch to be used. Where there is no reason to use another type, an endless type is recommended. The endless type is more economical and gives longer service life because of wear rotation.

3. Sling Width

If width is not a consideration because of load crushing or other reasons, use the narrowest sling that is rated to handle the load. Generally, a narrower sling is more economical.

4. Sling Length

Choker slings with metal end fittings must be of sufficient length to assure that choking action is on the webbing. Basket hitch slings must be of sufficient length to prevent overstressing of sling legs due to high sling leg angles.

5. Sling Body Ply

Body ply indicates the number of web thicknesses in the body of a sling. A rule of thumb is that for a given sling you can double the rated capacity by doubling the plies.

6. Accessories

Use accessories to solve specific sling problems. Refer to the table below and accessories on page I.17.

HOW TO ORDER

Specify:

1. Model Number (see example below)

2. Length (pull to pull)

3. Accessories: (if applicable)

A. Accessory order code (if applicable)

B. Accessory length (if applicable)

C. Position on sling (if applicable)

How To Order Caldwell® Web Slings

Standard Web Slings

End Fittings: Increase the life of web slings and fit on smaller crane hooks better than web eyes.

Standard Steel End Fittings: Plated, alloy steel end fittings are furnished on Type 1 or 2 slings.

Optional Aluminum End Fittings: Forged aluminum end fittings are available for single ply slings, widths 2” - 6”.

Unilink® End Fittings: Functions as both triangle and choker.

Type I: Basket and Choker Slings

Type I: Basket and Choker Slings

Type TC or UU

Type TT

Basket and Choker Sling

Triangle one end.

Choker triangle other end.

Basket Sling

Triangle each end.

Standard Web Slings

Type III:

Eye and Eye Slings

Type IV:

Turned Eye Slings

Standard Web Slings

Tapered Endless Sling TYPE ET

Two tapered points at opposite ends of the sling allow the use of wide slings on small crane hooks. However, the rotational feature of the sling is lost. Tapered points are for 1 & 2 ply slings only. Tapered points will be 1/3 sling width on medium duty and 1/2 sling width on heavy duty.

TYPE V: Endless Slings

Endless Type Slings TYPE EE

Endless Type Slings are one of the most versatile and widely used type because of their adaptability to numerous applications. They can be utilized in a choker, vertical or basket hitch. Sling life is prolonged because of rotation of the wear surfaces.

CAUTION:

Web slings must be used with compatible fittings, hooks, and shackles. Bunching of webbing reduces capacity. Please order Tapered Endless Sling (ET) or other style sling to accommodate for lifting hardware.

Standard Web Slings

Reverse Eye Slings have a texturized nylon wear pad on both sides which protect the main body from load abrasion, as well as adding significantly to sling life. Both eyes are open at 90° to sling body for ease of rigging. Reverse eyes can be used in basket or choker hitches. Eye lengths other than the standards listed are available, please specify.

TYPE VI: Reverse Eye Slings

Special Application Web Slings

Webbing Bridle Slings are lightweight and easier to handle when compared to wire rope and chain bridle slings. High quality forged fittings are selected to match the webbing rated capacities. Webbing Bridle Slings help absorb shock and do not conduct electricity. Standard slings are available in single, double, triple, or quadruple leg designs. Webbing Bridle Slings are particularly useful when fixed lifting points are available.

Single Leg Bridle Slings

Single Leg Bridle Slings Type SOS

Double Leg Bridle Slings Type DOS

Double Leg Bridle Slings

Special Application Web Slings

Three Leg Bridle Slings

Three Leg Bridle Sling Type TOS

Four Leg Bridle Slings

Four Leg Bridle Slings Type QOS

Special Application Web Slings

PRODUCT FEATURES:

• Quick and easy rigging.

• Sling wraps around pipe and hooks on itself.

• Pipe can be handled quickly and efficiently when properly balanced.

• Use in pairs for added stability.

• Complies with ASME standards.

Model QC - Quick Choke™ Pipe Lifting Sling With G-Link

Operation

Special Application Web Slings

PRODUCT FEATURES:

• Quick and easy rigging.

• Sling wraps around pipe and buckles together eliminating the need

to remove sling from hook.

• Pipe can be handled quickly and efficiently when properly balanced.

• Use in pairs for added stability.

• Complies with ASME standards.

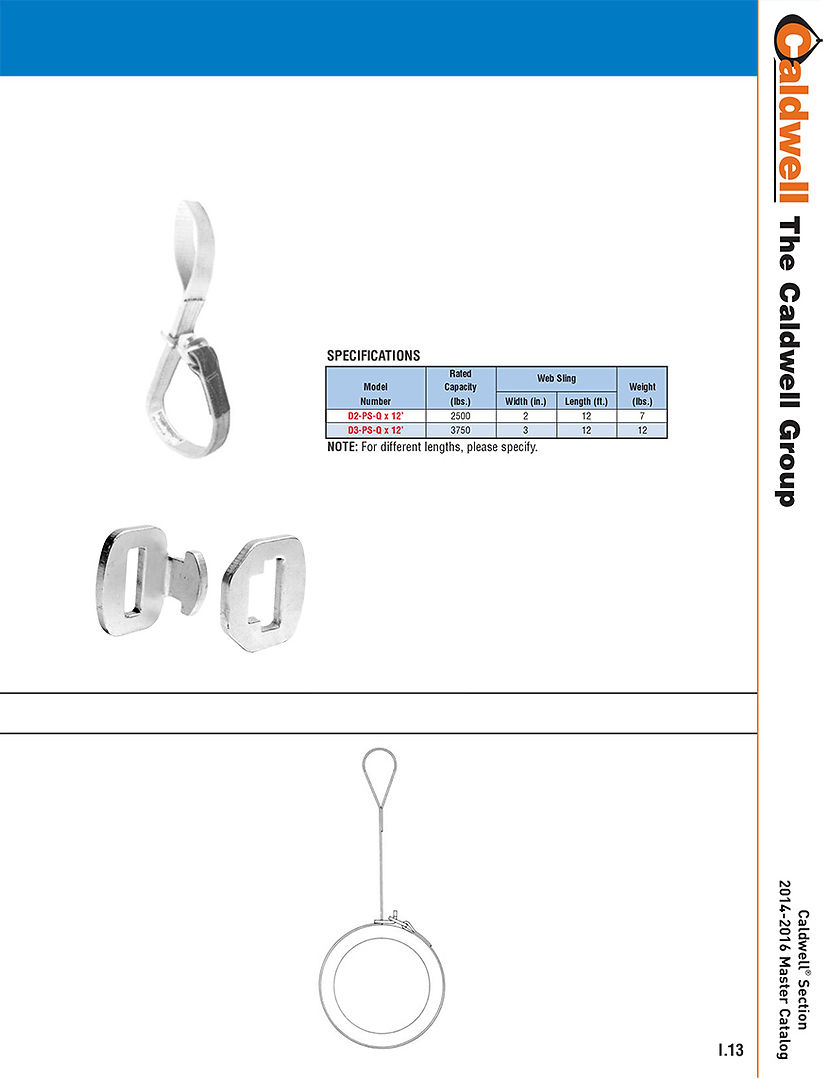

Model PS - Quick Disconnect Pipe Lifting Sling

With Quick Disconnect Buckle

Operation

Special Application Web Slings

Wide load slings support the load over a wide area to offer better balance for large loads – whether heavy or light. Wide bearing area reduces marring of soft load surfaces. Stiffeners are used at the base of the eyes to deter the body webbing from folding down the middle. Use only in a basket hitch.

Cargo Type Slings

Continuous Eye Wide Load Slings

Attached Eye Wide Load Slings

Special Application Web Slings

Fast loading, of most sized vehicles, is possible because of the lightweight, soft flexibility and tremendous strength made possible by using nylon

of various sizes.

Available in a wide range of lifting capacities, these wheel nets can be worked in a tight hold by hand folding the net into a bundle. Easily attach to the load by laying the Wheel Nets out and rolling the vehicle on or off the nets - no need for time consuming jacking. Steel links are at the lifting

points for wear resistance.

Wheel Nets

Wheel Nets are used in matched pairs.

Vehicle Lift Slings and Spreader Bars in capacities of 5-ton, 17-ton and 30-ton are available upon request.

Special Application Web Slings

Versatile Drum Handling Sling

This sling allows for easy handling of various sizes of steel drums and barrels, and has a 1,000 lb. capacity. It is light in weight, high in strength, and is resistant to oil.

Drum Handling Slings

PRODUCT FEATURES:

• Lightweight - weighs only 4 lbs.

• Versatile - lifts drums either vertically or horizontally.

• Self-tightening grip - sliding drum hooks tighten grip on load as drum is lifted.

• Tough - resistant to alkalis, ultra violet rays, rot and mildew.

Ratchet Type Drum Handling Sling

• Easily lift standing drums for transport.

• Tilt suspended drums to pour from open top or spigot.

• Use with ribbed steel drums, the ratcheting belly band tightens securely below the first rib.

• Standard wear pad for added protection.

• Ratchet tightens securely.

• Free end of ratchet strap sewn to stay properly threaded.

• Vertical legs sewn to belly band to maintain proper position.

Special Application Web Slings

Sling Accessories

The number one cause of synthetic sling failure is cutting. When slings are cut, property damage and personal injury or death can result. Wear Pads can help to reduce this problem by acting as a buffer between the load edge and the slings.

Sling protection accessories are available in a wide variety of materials.

P - A high density synthetic felt - 5/16” thick

W - Heavy nylon sling webbing - 3/16” thick

HL - Heavy leather - 5/32” thick

TN - Abrasion and cut resistant webbing - 3/32” thick

BN - Wear resistant fabric great for bundling - 1/16” thick

PVC - Non-absorbent - 1/8” thick

Flat Quick Sleeves - specify length

Flat Sewn Sleeve✝ - specify length.

Sewn-On Wear Pads✝ - specify length

Tubular Quick Attach Sleeves - specify length.

Protective Edgeguard✝

- specify length & location of edgeguard.

* Single & double ply only, for three and four ply slings go to next larger size.

Standard & Special Application Web Slings

Rated Capacity - Load Angle Charts

Angle factor must be applied to calculate the reduced sling capacity when lifting force is not at 900 to the plane of the load.

The rated capacities of the slings in this catalogue are given in the charts on the following pages. Since the capacity depends on how the slings are used, separate ratings are given for vertical, choker, and basket hitch lifts.

When selecting a sling to carry a given load, it is important to consider the angle at which the sling will be used. As the angle of the sling to the load changes, so does the capacity. For example: A sling rated at and lifting 1,000 pounds will be damaged - and could break suddenly when the lifting angle is less than 30° at which angle the slings capacity is reduced to only 500 pounds. Please use the following formula to calculate the actual capacity of the sling being used for your specific application.

ACTUAL CAPACITY OF HITCH =

Rated Capacity X Capacity Reduction Factor

Care & Use of Caldwell® Web Slings

USE:

• Check weight of load.

• Check sling rated load for type of lift, angle of loading (see load angle chart).

• Sling shall not be twisted, tied into knots or joined by knotting.

• Sling shall always be protected from being cut by sharp corners, sharp edges, protrusions or abrasive surfaces.

• Center load on base (bowl) of hook unless hook is designed for point loading.

• Balance load.

• Maintain load control.

• Avoid jerking the load.

• Be alert for snagging of load.

• Avoid dragging sling over rough surfaces and from under load.

• Choker hitch must choke on webbing never on fitting.

• Stand clear of load at all times.

• No person allowed beneath the load.

• Persons are not to ride on sling or load.

• If sling is to be used in a chemical environment, contact manufacturer for specific recommendations.

• Web slings must be used with compatible fittings, hooks, and shackles. Bunching of webbing reduces capacity

INSPECTION:

• Check tag for rated load adequate for the lift.

• Remove from service and replace is the following exists:

- Core yarn is visible.

- Webbing is cut, frayed, melted, charred or chemical damage is visible.

- Webbing has holes, tears, snags, or abrasions.

• Remove from service and repair if ID tag is missing or illegible.

• Frequent inspection shall be performed by a qualified person before each lift.

• Periodic inspection shall be performed by a qualified person at least annually and written records maintained.

CARE: Store in a cool, dry, dark area away from sun and any ultraviolet light source.

REPAIR: Only the sling manufacturer or qualified person shall make repairs.

Roundslings

Roundslings

PRODUCT FEATURES:

• Saves time, money and promotes safety in the

workplace.

• Super flexible, conforms to shape of load, flattens and

grabs the load securely.

• Soft cover won’t mar painted or polished surfaces or

cut hands.

• Lightweight and pliable for easy rigging and storage.

• Resistant to acids, ultra violet rays, rot and mildew.

• Good up to 194º F.

• Red striped, white core yarns allow for easy identification of damaged slings.

Sling Construction Details

Roundslings are constructed of a continuous, or endless loop of 100% polyester fiber (A). The multiple fiber construction makes the round sling

soft and flexible – conforming easily to almost any load surface.

The double-polyester fabric cover (B) protects the internal fibers. Sling replacement is not necessary until the red striped white core yarns can be seen through holes in the jacket. When core yarns are visible, sling must be removed from service.

In addition, the endless roundslings can be constantly rotated, further extending the wear life of the protective covering and the sling.

How To Order Caldwell® Roundslings

Specify:

1. Sling Model Number.

2. Sling length (bearing to bearing).

3. Quantity of slings.

4. Any additional information required to adequately describe order.

Roundslings

Endless Roundslings

Endless Roundslings

All the basic Roundsling features plus...

Additional jacket can help extend sling life if sling body abrasion has caused excessive wear in the past.

Eye and Eye Type EE

Endless Type EN

All the basic Roundsling features plus...

Endless Roundslings can be rotated to extend wear life.

Roundslings

Care & Use of Caldwell® Roundslings

CARE: Store in a cool, dry, dark area away from sun and any ultraviolet light source.

USE:

• Check weight of load.

• Check sling rated load for type of lift, angle of loading (see Load Angle Charts, page I.18).

• Sling shall not be twisted, tied into knots or joined by knotting.

• Sling shall always be protected from being cut by sharp corners, sharp edges, protrusions or abrasive surfaces.

• Center load on base (bowl) of hook unless hook is designed for point loading.

• Balance load.

• Maintain load control.

• Avoid shock loading.

• Be alert for snagging of load.

• Avoid dragging sling over rough surfaces and from under load.

• Choker hitch must choke on webbing never on fitting.

• Stand clear of load at all times.

• No person allowed beneath the load.

• Persons are not to ride on sling or load.

• If sling is to be used in a chemical environment, contact manufacturer for specific recommendations.

• Roundslings must be used with compatible fittings, hooks, and shackles. Bunching of webbing reduces capacity.

INSPECTION:

• Check tag for rated load adequate for the lift.

• Remove from service and replace is the following exists:

- Core yarn is visible.

- Webbing is cut, frayed, melted, charred or chemical damage is visible.

- Webbing has holes, tears, snags, or abrasions.

• Remove from service and repair if ID tag is missing or illegible.

• Frequent inspection shall be performed by a qualified person before each lift.

• Periodic inspection shall be performed by a qualified person at least annually and written records maintained.

REPAIR: Only the sling manufacturer or qualified person shall make repairs.

ENVIRONMENTAL CONSIDERATIONS:

• Nylon and polyester are seriously degraded at temperatures above 194° F and below -40° F.

• Many chemicals have an adverse effect on nylon and

polyester. This chart is a general guide. For specific

temperature, concentration and time factors, please consult

Caldwell prior to purchase or use.

WARNING: This product may contain chemicals known to

the State of California to cause cancer and/or birth defects or

other reproductive harm.

Wire Rope Slings

How to Order Caldwell® Wire Rope Slings

Specify:

1. Rope Diameter (inches)

2. Sling Length

3. Rope Construction

4. Number of Legs:

1—Single Leg

2—Double Leg

3—Triple Leg

4—Quad Leg

5. Attachments: Use 1 time for one end, 2 times for both ends

E—Loop Eye (no end fittings)

T—Extra Heavy Thimble

ST—Slip-Thru Thimble

TH—Thimble With Eye Hook

SCH—Choker Hook

CT—Cresent Thimble

OL—Oblong Link

Wire Rope Slings are the most common and lowest cost per ton of lift of all slings. Caldwell® Wire Rope Slings provide the strength and sturdiness required for lifting those tough loads. Used in the construction industry and other industries where heavy loads and rugged conditions exist. Available in many configurations with a variety of end fittings, Caldwell® Wire Rope Slings can be the solution to your load lifting requirements.

Wire Rope Slings

Wire Rope Slings

Caldwell® Wire Rope Slings are economical, general purpose, material handling slings which may be manufactured with a variety of fittings for use in many different configurations. The slings are manufactured with the flemish eye technique, giving the sling added strength should the swaged sleeve become damaged during use.

PRODUCT FEATURES:

• Reserve strength - integrity of eyes not solely dependent upon steel sleeves.

• Independent wire rope core resists crushing.

• When specified, thimble eyes protect wire rope from wear for increased life.

• Good abrasion resistance for longer life.

Wire Rope Slings

Bridle Slings

PRODUCT FEATURES:

• Bridles provide better load control and balance.

• Independent wire rope core resists crushing.

• Alloy steel hooks and links assure long life.

• Thimble eyes protect wire rope from wear for increased life.

• Reduces load damage by using fixed points on load.

• Easier rigging provided when hooking into fixed lifting points.

Wire Rope Slings

Care & Use of Caldwell® Wire Rope Slings

Tests have shown that whenever a sling body is bent around a diameter, the strength of the sling is decreased. D/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling.

The capacities in this catalogue are based on the minimum D/d ratios that appear below each of the capacity tables. For more severe bending conditions, contact Caldwell for revised capacities.

CARE:

• Store in a clean, dry place and protect from mechanical damage, extreme heat, corrosion or kinking.

• Keep sling lubricated.

USE:

• Check weight of load.

• Check sling rated load for type of lift, and angle of loading (see Load Angle Charts, page I.18.).

• Sling shall always be protected from being cut by sharp corners, sharp edges, protrusions or abrasive surfaces.

• Center load on base (bowl) of hook unless hook is designed for point loading.

• Balance load.

• Avoid shock loading.

• Maintain load control.

• Be alert for snagging of load.

• Avoid dragging sling over rough surfaces and from under load.

• Restrict use to temperatures below 400° F and above -40° F.

INSPECTION:

Remove sling from service if any of the following are visible:

• Ten broken wires in one rope lay or five wires in one strand in one rope lay.

• Wear or other loss of one-third of the original diameter of the individual wires.

• Evidence of heat damage or corrosion of rope (internal and external) or attachments.

• Kinking, crushing, bird caging, or any other damage resulting in distortion of the rope structure.

• End attachments, including hooks, that are cracked, deformed or obviously worn.

DO NOT inspect a sling by passing bare hands over the wire rope.

WARNING: These products may contain chemicals known to the State of California to cause cancer and/or birth defects or other reproductive harm.

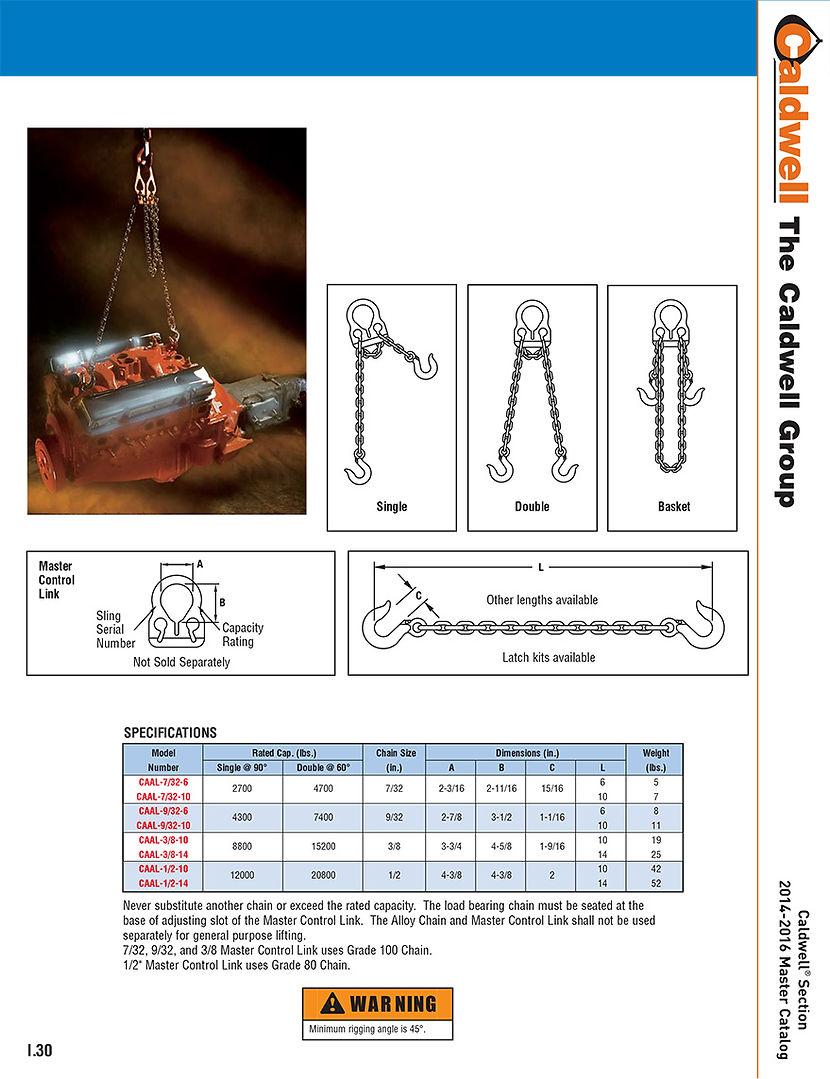

Alloy Chain Slings

Alloy Chain Slings – Superior strength slings, ease of handling and durability. Used in environments having severe lifting conditions such as foundries, steel mills, and heavy machining operations. Chain slings provide the longest sling life in the conditions commonly seen in these environments.

NOTE: Caldwell® Alloy Chain Slings are constructed using the best quality alloy steel, as designated by ASME. A Registered

Identification Tag is attached to each chain sling. This tag serves as a permanent identification for the life of the sling. Each tag is stamped with the grade, size, reach, type, work load (at a specific angle of lift), and a register number corresponding to the information supplied with the sling invoice. This provides the needed information for user compliance with OSHA requirements, and that all persons involved in the purchase and use of Caldwell® Alloy Chain Slings are aware of the specifications. All chain and component parts are proof tested to twice the catalogue working load limit.

PRODUCT FEATURES:

• Registered metal tag attached for identification and traceability.

• Long service life when used properly.

• Can be used in high temperature environments.

Specify:

1. Grade of chain - 80 or 100

2. Chain size - Inches

3. Number of legs -

Single - (S)

Double - (D)

Triple - (T)

Quad - (Q)

Choker - (C)

4. Master Link - Oblong (O)

or Specials -

Endless - (E)

Adjustable - (A)

Basket - (B)

5. Bottom Attachments -

Sling Hook With Latch - (SL)

Grab Hook - (G)

Foundry Hook - (F)

Latch Hook - (L)

6. Length of Assembly - Feet (Bearing point to bearing point)

Alloy Chain Slings

Grade 80 & 100 - Alloy Chain Slings

PRODUCT FEATURES:

Grade 80

• Proven reliability.

• Available in welded or mechanically assembled slings.

• Widest range of sizes and styles.

Grade 100

• Higher capacity per chain size.

• Extreme abrasion resistance.

• Shot blasted & oil finished for corrosion resistance & uniformed appearance.

Hardware Shapes - Dimensions

Oblong Link Foundry Hook Sling Hook Grab Hook Latch Hook

Alloy Chain Slings - Grade 100

Single Chain Slings

Double Chain Slings

Triple and Quadruple Chain Slings

Alloy Chain Slings - Grade 80

Single Chain Slings

Double Chain Slings

Triple and Quadruple Chain Slings

Alloy Chain Slings

Adjust-A-Link

PRODUCT FEATURES:

• Versatile assembly does many jobs.

• Easily adjustable to accommodate a wide range of applications.

• Heat-treated alloy steel construction.

• Powder coating of Master Control Link helps prevent rust.

• Plate is permanently stamped with capacity and serial number.

Alloy Chain Slings

Care & Use of Caldwell® Alloy Chain Slings

CARE:

• Store on a rack in a clean, dry place.

• Oil prior to prolong use.

• Do not anneal (temper) alloy chain, connecting links or hook(s). Hot galvanizing requires chain manufacturers advice.

USE:

• Check weight of load.

• Check sling rated load for type of lift, angle of loading (See Load Angle Charts, page I.18.).

• Avoid twists, knots or kinks.

• Center load on base (bowl) of hook unless hook is designed for point loading.

• Balance load.

• Avoid shock loading.

• Be alert for snagging of load.

• Maintain load control.

• Pad sharp corners.

• Keep load off sling.

• Avoid dragging sling over rough surfaces and from under the load.

• Stand clear of the load at all times.

• No person allowed beneath the load.

• Persons are not to ride on sling or load.

• When shortening chain, use only the manufacturer’s recommended alloy components.

• For use in temperatures over 400° see chart for capacity reduction.

Examples Of Chain Sling Abuse/Wear

Remove Sling From Service...

CHAIN WEAR ALLOWANCE

Determine wear by measuring cross section at link ends. If worn to less than the minimum thickness allowable, chain should be removed from service.

Worn Links

Excessive wear, especially at the bearing points, seriously weakens the chain.

Gouged Links

Damaged by a heavy object being dragged over or dropped on the chain.

Bent Links

Usually caused by bending over sharp edges of a load.

Stretched Links

Indicates the chain has been extremely overloaded or subjected to shock loading. These links would not hinge freely with adjacent links.

Wire Mesh Slings

Specifications

PRODUCT FEATURES:

• Resists abrasion and cutting for greater sling life.

• Low stretch and good flexibility reduce load damage.

• Wide bearing area distributes load to help avoid load damage.

• Alloy steel end fittings - plated for long life.

• Wire mesh is zinc plated - resists corrosion.

• Each sling permanently stamped with capacity and serial number.

• Each sling proof tested and certified.

• Width of mesh helps control and balance load.

• Repairable - thus very cost effective.

Applications

Wire Mesh Slings

How To Order Caldwell® Wire Mesh Slings

Specify:

1. Sling Model Number.

2. Sling length (pull to pull).

3. Specify type (1 or 2).

4. Quantity of slings.

5. Any additional information required to adequately describe order.

Care & Use of Caldwell® Wire Mesh Slings

CARE:

• Store in a clean dry area to avoid corrosive action.

• Do not use at temperatures above 550° F or below -20° F.

USE:

• Check weight of load.

• Check sling rated load for type of lift, and angle of loading (See Load Angle Charts, page I.18).

• Pad sharp corners .

• Balance load.

• Maintain load control.

• Avoid shock loading.

• Be alert for snagging of load.

• The choker fitting must not be positioned against a load edge or directly

on the triangle fitting.

• Stand clear of load at all times.

• Do not lift over people.

INSPECTION CRITERIA:

Before each use - check that rated loads are marked on end fittings. Remove the sling from service if any of the following are visible:

• Broken weld or brazed joint along the sling edge.

• Broken wire in any part of the mesh.

• Reduction in wire diameter of 25% due to abrasion or 15% due to corrosion.

• Lack of flexibility due to distortion of the mesh.

• Visible distortion, wear, or cracks in either end fitting.

10 Gage - Heavy Duty

Repair Service Available

Cargo Tie Downs

Web Strap Systems

• IN PLANT

• VEHICLES/TRAILERS

• FLATBED TRUCKS

Your Assurance of a Secure Cargo

Caldwell® Cargo Tie-Downs can satisfy just about every cargo-securing requirement whether your cargo is heavy or lightweight, bulky or small... whether it is transported by truck, rail, airplane or ship for long hauls or by forklift just around the corner. Highstrength webbing is available in a number of widths from 1” to 4” and tensile strengths from 1,000 to 20,000 lbs. With our large assortment of end fittings, tighteners and optional accessories, binding tasks are quick and easy, usually enabling one person to tie down the payload. Rugged Caldwell® Cargo Tie-Downs are resistant to rotting and mildew, and are non-marring, providing reliability and long service life that your cargo-securing demands.

Properties

1. Web Material

Web straps are soft, flexible and nonconductive. Straps are made from polyester and nylon yarn, which is woven into various widths and thicknesses.

2. Coating Treatment Of Web Straps

Nylon and polyester straps are latex treated for surer grip and resistance to wear and abrasion.

3. Strength

Working Load Limit: The maximum load that may routinely be applied to an assembly or component in straight tension. Ultimate Strength: The load at which an assembly or component will fail in testing.

A CARGO TIE-DOWN ASSEMBLY STRENGTH IS RATED AT THE LOWEST COMPONENT IN THE STRAP ASSEMBLY.

4. Metal Components

The various tighteners and end fittings making up the assembly have been treated to prevent rust.

5. Accessories - Protective Boots - Ratchet Pads And Corner Protectors

Protective Boots - fit over the webbing to prevent cutting and wear by the edges of the cargo. Boots slide on the webbing to allow proper placement of boot in relation to the cargo edges. See page I.17 for details.

Ratchet Pad - prevents the metal ratchet from marring the cargo. The pad attaches directly to the underside of the metal ratchet. Add RP to order code.

Corner Protectors - movable rust proof copolymer.

Protects tie downs from sharp corners. Add CP to order code.

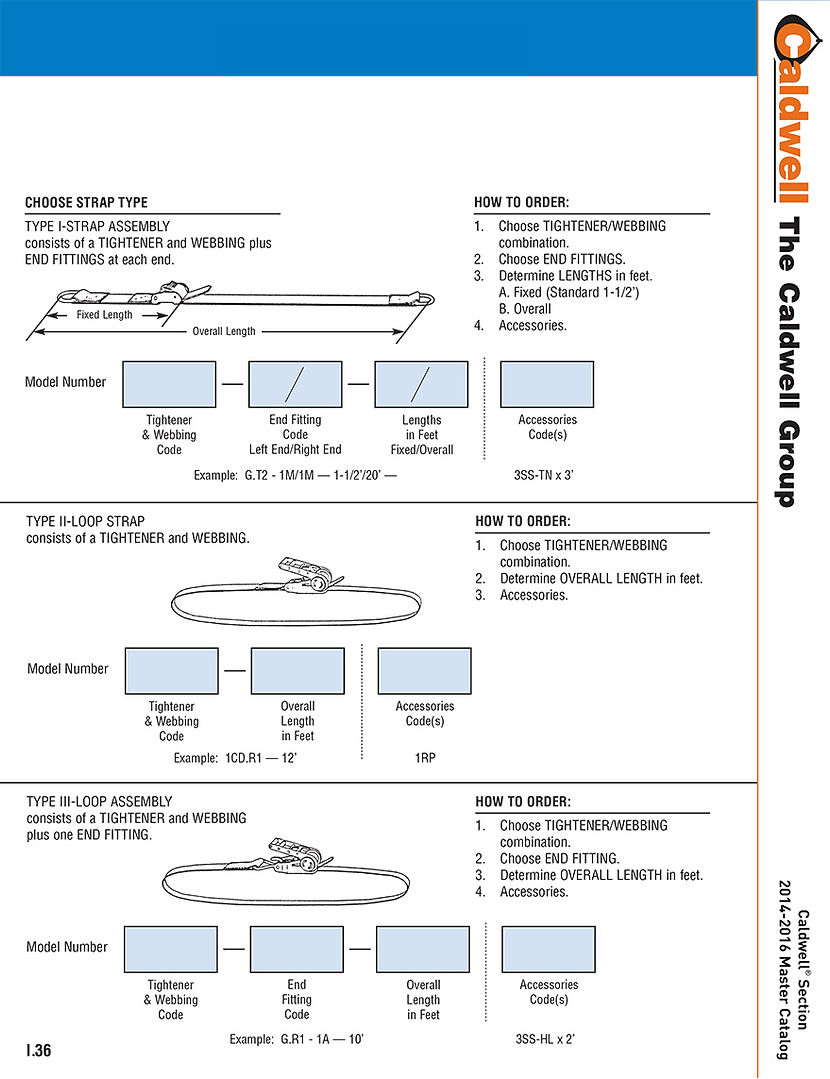

STRAP ASSEMBLY — TYPE I

Consists of a Tightener and Webbing plus End Fittings at each end.

Application: Used to attach at two different hold down points and is tightened down over cargo.

LOOP STRAP — TYPE II

Consists of a Tightener and Webbing.

Application: Used to go around cargo and hold pieces together.

LOOP ASSEMBLY — TYPE III

Consists of a Tightener and Webbing plus End Fitting at

one end.

Application: Used to go around cargo and attach to one hold down point or attach fitting to tightener.

WINCH SYSTEMS — TYPE IV

Consists of a Winch and Webbing plus End Fitting at one end.

Application: Used on flat bed trucks; winch is secured to truck; end fitting hooks into attachment point and webbing is tightened down over cargo.

Care & Use of Caldwell® Tie-Downs

CARE: Store in a cool, dry dark area away from sun and any ultraviolet light source.

USE:

• Check weight of load.

• Check tie down working load limit.

• Never exceed rated capacities.

• Tie down shall not be twisted, tied into knots, or joined by knotting.

• Tie down shall always be protected from coming in contact with rough or sharp edges.

• Load should be securely blocked and stabilized before tensioning the straps.

• Re-tighten tie downs periodically during run.

• All hardware must be in line with direction of pull to achieve full strength.

• Never use assemblies for anything other than securing cargo. Do no use for lifting loads or towing vehicles.

• Tie downs are not rated for overhead lifting.

• Proper tie down methods should be used in accordance with federal and applicable state regulations.

INSPECTION:

Tiedown inspection records shall be established by the user.

Types Of Inspection:

1. Initial - Before any Tie-Down is placed in service it shall be inspected to insure that the correct tiedown is being used as well as to determine that the tiedown meets the requirements of this specification.

2. Frequent - Inspection should be made by a qualified person each day before each shift.

3. Periodic - Inspection shall be conducted by a qualified person.

Frequency of inspection should be based on:

A. Frequency of use.

B. Severity of service conditions.

C. Experience gained on the service life of tie-downs used in

similar applications.

D. Inspection should be conducted at least monthly.

REMOVE FROM SERVICE:

A tiedown shall be removed from service if any of the following are visible:

• Acid or alkali burns.

• Melting, charring, or weld spatter on any part of the webbing.

• Holes, tears, cuts, snags or embedded particles.

• Broken or worn stitching in load bearing sew patterns.

• Excessive abrasive wear.

• Knots in any part of the webbing.

• Distortion and excessive pitting or corrosion or broken fittings.

• Other apparent defects which cause doubt as to the strength of the tie down.

Cargo Tie Downs

Cargo Tie Downs

Light Duty 1” Web Strap Systems

Strength 1,000-3,000 lbs. Caldwell’s Light Duty Straps provide an ideal reusable strap for in-plant hold-down applications, at an economical cost. Examples: securing stacked boxes on pallets, binding together or segregating loose bars or bundles, securing cylinders upright, securing a ladder against falling.

Cargo Tie Downs

Light Duty 1” Web Strap Systems

End Fittings

Cargo Tie Downs

How To Order Caldwell® Wire Mesh Slings

Strength 2,000-5,000 lbs. Caldwell’s Medium Duty Straps are used for the heavy moves, such as machinery or where movement can generate a substantial force against the tie-downs, as on a vehicle.

Cargo Tie Downs

Medium Duty 2” Web Strap Systems

End Fittings

Cargo Tie Downs

Heavy Duty & Flat Bed Truck Tie Down Systems

Polyester Web Strap Ratchet & Winch Assemblies

Caldwell® Polyester Straps secure loads efficiently, do not mar, and stretch less than nylon straps. Straps are highly visible yellow and conform to California and Federal specifications. Polyester Straps are available with multiple end fitting configurations.

Ratchet Systems

Heavy Duty & Flat Bed Truck Tie Down Systems

End Fittings