CONTACT DETAILS

National Tel : 0861040506

International Tel : +27117925226

Cellular : 0832514312 / +27832514312

info@liftlash.co.za

PAGE NAVIGATION

FALL ARREST - PETZL complete catalogue

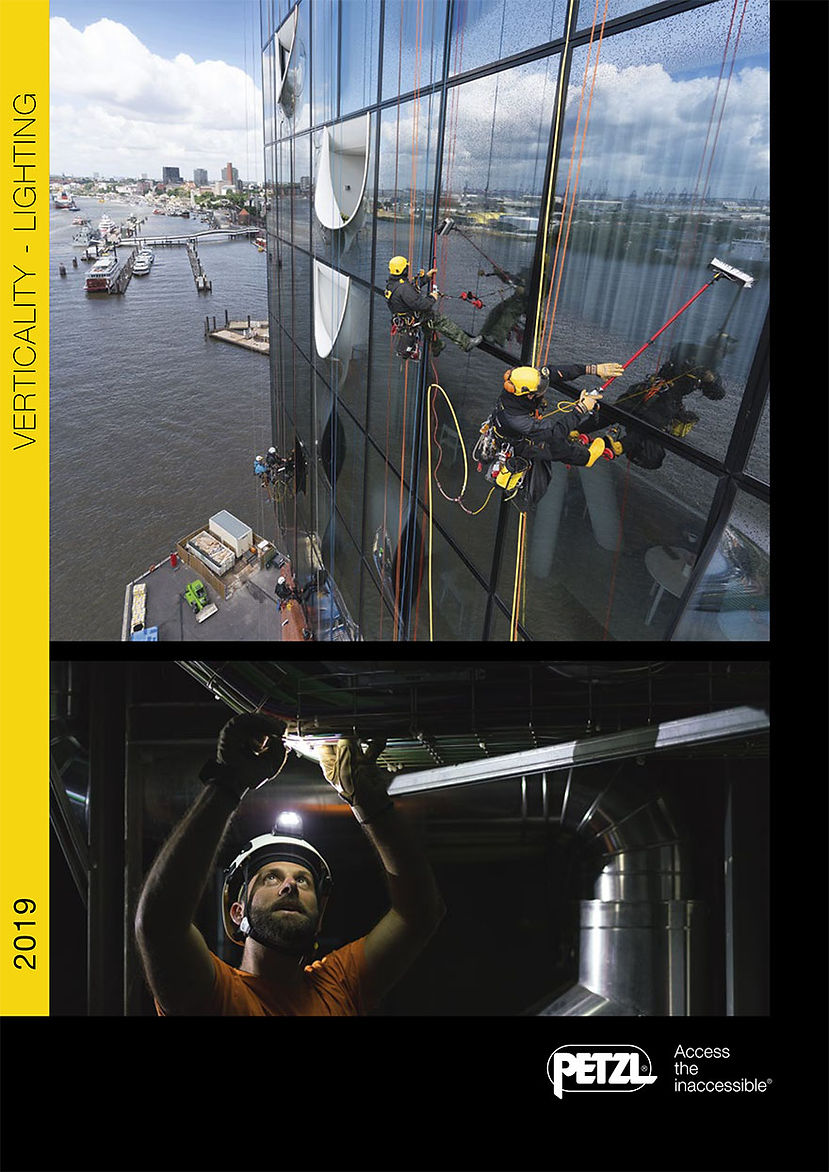

In the realm of work at height, especially in areas related to progression on rope, performance and ergonomics are major issues.

At Petzl, we maintain a constant contact with professionals, which allows us to create solutions to meet these needs. For 2019,

we have focused our efforts on multiple product families. With the advent of the new VERTEX and STRATO helmets, Petzl introduces

a new line available in different configurations (VENT, HI-VIZ...) with an extensive selection of accessories (visors, nametag holder,

nape protector...). Also of note for rope access, the new I'D descenders with AUTO-LOCK function and the international versions

of the AVAO and ASTRO harnesses. For tree care, the line received a major overhaul: new SEQUOIA harnesses with accessories,

two versions of the ZIGZAG mechanical Prusik. Safety is a necessity for lighting as well, which is why we developed the PIXA Z1 headlamp for hazardous areas.

Happy reading.

Access the inaccessible.

Expertise and dedication to quality 6

VERTICALITY

General principles of work at height 12

Rope access and confined space 14

Tree care 20

Energy and networks 24

Framing and roofing 28

General rescue principles 32

Self-rescue 34

On-site rescue 36

Technical rescue 40

Ski lift evacuation 44

Harnesses 48

Helmets 68

Lanyards and energy absorbers 80

LIGHTING

A line for every activity 154

The Petzl difference 155

Petzl quality 156

Brightness and burn time 157

Environments and standards 158

Headlamp specifications 161

Performance headlamps 164

Compact, durable headlamps 170

Ultra-compact headlamps 176

Product index 182

From the Deep: The Petzl Adventure 184

Key new products for 2019

Helmets

New lines of VERTEX and STRATO helmets, accompanied by a range of entirely modular accessories that meet the varied needs of professionals.

Descenders

Self-braking I’D descenders now have an AUTO-LOCK function. New ZIGZAG mechanical Prusiks come with a range o f accessories that allow even greater efficiency when moving through trees.

Harnesses

New SEQUOIA tree care harnesses offer improved comfort and great mobility. AVAO BOD / AVAO BOD FAST and ASTRO BOD FAST harnesses are now available in international versions.

Connector

New Bm’D carabiner for connection to equipment such as descenders or positioning lanyards

Headlamp

Compact, durable PIXA Z1headlamp for use in ATEX hazardous areas, suitable for proximity lighting, movement and long-range vision

Access the inaccessible.

Petzl’s mission is to create innovative tools and services that allow men and women to progress, position, and protect themselves in vertical environments, as well as to light their way in the dark. We continually look for the best solutions for user needs in terms of performance, ergonomics, comfort, and reliability. The demands and the commitment of users are what guide our approach to supporting them in their pursuit of the inaccessible. We have stood by their side for over 40 years.

Paul Petzl

Petzl: a family's passion

Access the inaccessible.

The Petzl signature on a product has always represented the commitment of the Petzl family to produce the best tools for its users. The adventure began with Fernand Petzl's passion for caving, a passion to which he dedicated his talents as a craftsman. Petzl expertise began to grow with the design and crafting of solutions for ascending, descending, belaying and moving about in the dark. In 1970, the first "Fernand Petzl" brand products were produced in a workshop in Saint-Nazaire-Les Eymes, Isère, France. The Petzl company was created in 1975 and has grown into an international company that now employs over 800 people. Since its beginnings, it has preserved its family legacy and values: remaining independent and in control of its own decisions, developing a long-term vision, prioritizing people above all, and embracing its commitment to quality. Today, a family council, with Paul Petzl as president, ensures the continuity of the company.

A pioneering business

To attain the inaccessible, you need to know how to reinvent yourself. Since the development of the first rope ascenders and descenders, which laid the foundation for rope progression, Petzl has been at the forefront of change and the emergence of new techniques. Headlamp lighting, belaying, rescue, ice climbing, glacier travel... In these and other fields, Petzl's innovations have allowed equipment to evolve and practices to be reinvented. As proof of this dynamic activity, 700 patents have been

registered since 1970.

These advances always result from a dialogue with the user, in order to understand his/her expectations and to provide the elements s/he needs. Petzl has always remained true to this method. Petzl's philosophy for design and production is also based on accelerating change, transforming, and innovating in order to provide sports enthusiasts and professionals with the quality products they demand. Testing tower, experimentation center, individual inspections, LEAN manufacturing process - Petzl was a pioneer in all of these innovations.

Education, communication

From the beginning, we have sought to provide technical answers to our users' needs. The answers come in the form of product design, but also in the sharing of our experience with verticality. This experience can be found in the technical notices for products, and in the technical advice in our catalogs and at Petzl.com

The Petzl Solutions department is dedicated to education, through the sharing of our technical expertise. Petzl Solutions provides technical education modules and makes them available through a network of Petzl

Technical Institutes around the world.

In order to share our values, we collaborate with top athletes in different disciplines. Mountaineers, climbers, trail runners, cavers... they are the ambassadors of our company and of the passion for the inaccessible. Many are involved with the fine-tuning of our products. See them at Petzl events and through their stories on Petzl.com and on our social media platforms.

1936: Fernand Petzl starts exploring the Dent de Crolles, France, and invents the tools he requires

1968: Our first rope ascenders and descenders (BASIC, SIMPLE) under the name Produits Fernand Petzl (Fernand Petzl Products)

1973: First Petzl mountaineering headlamp is developed

1983: First Petzl harnesses

1991: GRIGRI®, first belay device with assisted braking

1998: TIBLOC®, ultra-compact rope clamp

2001: First TIKKA LED headlamp®

2004: ASAP® mobile fall arrester

2005: Petzl professional helmets

2006: EXO® personal escape system for New York City firefighters

2012: NAO® headlamp with REACTIVE LIGHTING technology

2013: SIROCCO helmet and ZIGZAG® mechanical Prusik for tree care

2015: SITTA harness for climbing and technical mountaineering

2017: GRIGRI® + belay device

2018: New DUO headlamps with FACE2FACE anti-glare technology

For over 40 years, Petzl has built on its expertise in the design and manufacture of products for verticality and lighting. Today, Petzl designs, produces and distributes millions of products around the world. Building a Petzl product requires expertise in a wide range of materials - textiles, metals, plastics - as well as in specific technologies: plastics processing, sewing, injection molding, forging, LEDs, electronics... This expertise allows us to design equipment that meets both the needs of users and the technical requirements for its use: resistance to impacts, abrasion, extreme temperatures...

Expertise and dedication to quality

Design

The Petzl research department in Crolles, France, integrates all the fields related to product design: mechanical, textile,

electronic, optical, computing and prototyping. Starting at the design and prototype phases, the reliability of the product and user safety are continually evaluated with a strong focus on risks to the user.

Testing

In Crolles, Petzl has labs dedicated to testing verticality products and headlamps. These tests often go above and beyond the required standards to help validate product reliability and user safety. Examples of tests: dynamic fall tests, impact resistance, cyclic testing, performance, headlamp beam quality and burn times. They are complemented by testing in the field for ergonomics and reliability.

SPECIAL INDUSTRIAL SUPPLIES PTY LTD.

Tel National: 0861040506

Tel International: +27117925226

Cell: +27832514312

Unit 21, Acacia Industrial Park

17 Arbeid Avenue, Strydom Park.

South Africa.

Production and

inspection

Petzl's production sites are based in Crolles, Eybens, and Rotherens, France, and in Rawang, Malaysia. This production infrastructure is complemented by longterm partnerships with key suppliers in Europe and Asia. Our purchasing and quality control teams work closely with suppliers to guarantee a standard of product reliability and quality that meets our strict requirements. During the manufacturing phase, quality control is present at every step of the production chain. It combines automated and human inspections.

Serving our communities

Providing solutions for users

Petzl serves communities of users committed to their activities. Our goals:

to assist them with products they can rely on, and to offer them our expertise.

Petzl is active in the following fields:

• outdoor activities: climbing, mountaineering, ski mountaineering, trail running, via ferrata, canyoning...

• work at height: rope access, tree care, energy and networks, framing and roofing...

• rescue: technical rescue, self-rescue, evacuation on mechanical lifts

• personal lighting for professionals,

for maintenance, for industrial worksites

• equipment for tactical operations units

• equipment for adventure parks

The Petzl Foundation

Finding new directions

In the depths of the Masaya volcano

In 2015, a lake of lava appeared in the Masaya volcano in Nicaragua. The proximity of a vast expanse of lava offered researchers the chance to study the gases emitted by the volcano, from their generation to their dissipation in the environment.

In July 2017, the International Volcano Monitoring Fund and the GeoArc Foundation association, experts in difficult-access scientific expeditions, assembled a multidisciplinary team of researchers and technicians who are skilled in work at height. Together, they designed and installed an aerial system to deploy sensors into the depths of the Masaya volcano's crater. 1.2 km of rope was required to set up an aerial tram spanning the 500-meter-wide crater in order to take samples at a depth of 400 meters. Using this device, sensors were positioned in the acid plume above the lava lake. Additional sensors, below the vent and around the sides of the volcano, yielded a profile that precisely evaluates the concentrations of toxic gases. This profile will provide a better measurement of the gases' impact on the surrounding villages and a large part of Nicaragua.

Supported partners: International Volcano Monitoring Fund and the GeoArc Foundation

Location: Nicaragua

Support: 20,300 € in 2017

Read about all Petzl Foundation projects at www.fondation-petzl.org

Climbing towards a summit or progressing in the vertical world gives rise to lasting passions that help women and men grow, thrive and dream. For over 10 years, the Petzl Foundation's mission has been to support or initiate projects of public interest through its activities in the mountain and vertical spheres, projects that help bring balance to humankind's place in its natural, cultural, and economic environments.

The Petzl Foundation:

- encouraging learning and risk management to avoid accidents

- promoting the preservation of hard-to-access ecosystems

- contributing to a better understanding of current practices and their environments

Petzl's expertise in vertical terrain is expressed by its line of products specifically designed for work at height and rescue professionals. These products address all of the issues faced by professionals every day: repeated and intensive use of equipment, weather, diverse terrain... They maximize usability, simplicity and ease of use, while meeting the highest quality standard.

Equipment inspection and individual

identification code

To ensure that your equipment is in good condition throughout its useful lifetime, it is necessary to inspect it regularly. Depending on the product's date of manufacture, the individual identification code can be structured in two ways, with 11 or 13 characters.

For more information, please see www.petzl.com

Special products in black

Certain products are also available in black; they are designed for professions where stealth is essential

Product customization and adaptation

The Petzl Customization service is for professionals who have specific needs,outside of the standard product offering:

product marking and adaptation...

For more information: contact us

VERTICALITY

General principles for work at height

Warning

• You must have understood and retained the information from your products' Instructions for Use to be able to apply the techniques presented in this document

• Learning appropriate techniques and methods of protection is your own responsibility. Petzl solutions are given for information only, with no guarantee of their effectiveness in your specific working situation. The relevance of these solutions varies by context, so always do your own risk analysis in the field

• Mastering the techniques presented here requires specific training and practice; consult a specialized organization for all training activities

General information on falls

The risk of falling is a key concept to master when working at height. The severity of a fall depends on independent factors:

• The weight of the user, including equipment:

The greater the weight, the more energy to be dissipated during the fall.

• The length of the fall:

The longer the fall, the more energy to be dissipated during the fall. The risk of hitting an obstacle is also greater.

• The position relative to the anchor:

When the worker moves above his/her anchor, the severity of the potential fall increases. The fall factor concept is sometimes used to describe the worker's position relative to the anchor and the severity of the fall. This concept applies to climbing, restraint, or work positioning situations, when a dynamic rope lanyard is used.

Precautions for the type of system used:

The Instructions for Use specify the limitations for use of equipment, particularly in terms of fall distance and the worker's position relative to the anchor.

Restraint

A restraint system limits the work zone, keeping the worker from entering an area that may present a risk of falling. This system is not designed to arrest a fall from height.

Fall arrest

The fall arrest system is a belay system that is independent of the means of progression or work positioning. The fall arrest system prevents the user from falling to the ground in case of a fall. Its role is to arrest the fall while limiting the impact force experienced by the user. It must therefore be used with enough clearance to allow for a free fall.

Work positioning

A work positioning system supports the user and allows him/her to be precisely positioned with weight on his/her feet. This system is not designed to arrest a fall; the user must keep his/her body weight on the positioning system. The work positioning system must be supplemented with a fall arrest system.

Suspension

The user is working in suspension when s/he no longer has weight on his/her feet,

but is supported primarily by the harness.

The load is thus shared between the waistbelt and the leg loops/seat

Impact force

A fall arrest system allows the impact force experienced by the user to be limited.

It is typically composed of an energy absorber that tears in order to limit the forces over a specific stopping distance.

A dynamic rope lanyard has a low capacity for energy absorption. Its use requires great precautions: reducing the potential fall distance and staying in a work position below the anchor.

A webbing lanyard or a cable, with no capacity for energy absorption, can not be used to arrest a fall.

Clearance

Clearance is the minimum amount of clear space below the user that prevents the user from hitting an obstacle in case of a fall.

Clearance takes into account:

- the user's weight

- the length of the fall

- the tearing length of the energy absorber

- the average height of the user

- a safety margin of 1 meter

Clearance value

The tearing length of the energy absorber, depending on the the fall, can only be known based on the manufacturer's information; this is why a clearance estimate is suggested in the Instructions for use for each fall arrest device.

Anticipating the means of rapid evacuation

• Limiting the effects of inert suspension:

In case of a fall where the worker loses consciousness or is incapacitated, inert suspension in the harness presents a mortal danger requiring an urgent response. Work teams must be equipped and trained to quickly evacuate an injured team member.

• Evacuating a victim without assistance:

Procedures for evacuating workers should be determined whenever a new worksite is established.

Releasable systems can be created during installation of working ropes

to allow evacuation from below.

Working alone must be prohibited: a worker may find him/herself alone at height, but at least one person trained in evacuations should be present and equipped on site.

Rope access and confined space

Rope access work situations often involve environments at significant height. They can be inside or outside, even confined, and are not suited for the use of collective protection. Work done in confined spaces carries additional difficulties related to

the lack of space, and to the lack of means of autonomous progression.

Examples of operations:

• placement of rockfall or stabilization nets over a road

• structural inspection (bridge pilings...)

• exterior window cleaning on skyscrapers

• inspection of tanks

Technical specifics:

• the work area is accessed with ropes by specialized workers trained in rope access techniques

• access from above is preferred as it is safer and simpler to set up

I'D S and Open auxiliary brake

The self-braking I’D S descender is designed for work at height and rope access work. It has an ergonomic handle that allows convenient descent control. The integrated anti-panic function and anti-error catch limit the risk of an accident due to user error. The AUTO-LOCK system allows users to easily position themselves at the work station without having to manipulate the handle or tie off the device. The open auxiliary brake may be used to increase braking friction, depending on the load and on the rope diameter.

Rope access

Installing ropes

Load-sharing anchors with the rope.

Installing a lifeline with the ASAP mobile fall arrester.

Rope access

Gated ventral attachment point on ASTRO harnesses

The ventral attachment point on ASTRO harnesses is gated for optimal integration of equipment

Serving our communities

1. Combined lowering/raising system

• Advantage: quick transitions between modes (lowering/raising)

• Disadvantage: rope length is four times the travel distance

2. Independent lowering/raising systems

• Advantage: the length of the rope equals the travel distance

• Disadvantage: rigging is required to transition between lowering and raising

ZIGZAG PLUS and CHICANE

Serving our communities

Not all tree work can be done using exterior means such as elevated platforms or ladders. In this case, to move and work, the arborist uses rope progression techniques.

Examples of operations:

• ornamental tree trimming, to adapt the tree to its environment or to change

its overall aesthetic

• maintenance trimming to remove dead wood and dying branches

• tree removal (progressive cutting of the trunk from the top) if diseased or presenting a hazard...

Technical specifics:

• access from the base of the tree generally starts by throwing a weighted bag with line attached. This line is used to install the access rope on an anchor up in the tree

• while moving about on the branches, the arborist keeps his/her weight on the work rope, for greater stability and to reduce the potential fall distance

• when using any cutting tool (hand saw, chainsaw), the arborist must use two independent belay systems

The ZIGZAG PLUS mechanical Prusik allows the user to move around efficiently in a tree. The friction chain provides precision and fluidity when moving around. The pulley allows the slack to be taken up easily. Can be used on either doubled ropes or a single rope, providing great versatility. The lower attachment hole with high-efficiency swivel ensures stable and correct positioning of the mechanical Prusik and optimal rope glide through the device. The CHICANE auxiliary braking device allows ZIGZAG and ZIGZAG PLUS mechanical Prusiks to be used on single ropes. It provides continuous additional friction on descents.

Tree access

Tree care

Doubled rope ascent technique

The arborist ascends the access rope (purple). In case of a hornet attack (or other problem) s/he can self-evacuate with the work rope (blue). A mule knot, or releasable knot, secures the ZIGZAG. This versatile ascent technique is adaptable to many situations and allows an access rope to be available during work.

Single rope ascent technique

The access rope is attached to the base of the tree and runs through an appropriate anchor in the tree. It will also be used for work. On single rope,

the ZIGZAG must only be used with the CHICANE. This technique allows for rapid rescue and efficient climbing with the KNEE ASCENT knee ascender.

Movement within the tree

Movement on doubled rope

The work rope is set up doubled through a false crotch,

on a suitable anchor near the top of the tree. This technique allows for easy travel in any direction and provides the arborist with good support when limb walking

Movement on single rope

The rope setup does not change between access and work; if the top anchor is reliable and verified, the arborist does not necessarily need to

climb to the top and can go directly to the work station. The rope does not run during movement, the arborist can thus move anywhere in the tree

with no loss of efficiency.

VERTEX VENT HI-VIZ and VIZIR

Energy and networks

These fields are characterized by structures such as towers, antennas and windmills. The modes of progression are varied, and directly related to the structure itself.

Examples of operations:

• work on high tension lines

• tower construction

• maintenance operations in wind farms...

Technical specifics:

• the user generally progresses using lifeline, cable or rail type permanent fall arrest systems

• lacking these, the user must ensure his/her own safety using personal protective equipment:

energy-absorbing lanyard or mobile fall arrester on rope

The VERTEX VENT HI-VIZ helmet is very comfortable, thanks to its six-point textile suspension and ENTERFIT and FLIP&FIT systems, which guarantee that the helmet fits securely on the head. It has ventilation holes with sliding shutters to allow airflow through the helmet. The high visibility version features a fluorescent outer shell with phosphorescent clips and reflective bands, for optimal visibility of the worker, day or night. The VIZIR eye shield protects the eyes against projectile hazards. It is easy to install with the EASYCLIP attachment system.

Energy and networks

Backed-up ascent using a double lanyard with integrated energy absorber

Ascent protected by a fall arrest trolley attached to a rail

The trolley is fixed to the harness's ventral fall arrest attachment point (LADDER CLIMB), distributing the load on the waistbelt and ensuring optimal comfort during progression. In case of a fall, this attachment point moves upward to a sternal position to ensure a vertical post-fall body position.

Backed-up progression using a double lanyard with integrated energy absorber

To reduce the risk of a fall, the two arms of the energy- absorbing lanyard are attached on both sides of the user.

Belaying with the ASAP LOCK for tower access

Belaying the climber's ascent

AVAO BOD FAST international version

Framing and roofing

In this type of work situation, the risk of slipping and falling is higher. A safety device must be installed to guard against these hazards.

Examples of operations:

• framing a building under construction

• roof repair or waterproofing

• roof inspection on industrial sites...

Technical specifics:

• when the situation allows, accessing the work area is done using an elevated work platform.

The worker secures him/herself with an energy-absorbing lanyard

• lacking collective protection, the worker is required to use a fall arrest system

• fall arrest systems are also required when installing collective

protection

The AVAO BOD FAST fall arrest, work positioning and suspension harness is designed for greater comfort in all situations. Wide, semi-rigid waistbelt and leg loops give excellent support. The lightweight, breathable construction maximizes air flow. The shoulder straps have a system for stowing the fall arrest lanyard connectors and keeping them within reach. The harness has a fall indicator on the dorsal attachment point.

Framing and roofing

1. Roof access

Installing a rope with releasable

anchor; backed up ascent with

the ASAP.

2. Long-term use

With individual positioning system and collective protection.

3. Occasional use

With individual fall arrest system

General rescue principles

Inert suspension in a harness, even for a short time, can cause

serious physiological harm. In case of an accident, it is important

to respond quickly with the appropriate technique.

Self-rescue

On sites where the main access could be cut off by fire, people must be ready to quickly evacuate the building. They have evacuation kits. These kits are either portable or installed permanently on the structure. Where there is no identified anchor possibility, a hook-based system can be used. In both cases, teams must be regularly trained so as not to panic in case of a fire.

On-site rescue

When a worksite is being set up, the company must establish a risk prevention plan (inventory of risk situations):

1. It must protect the personnel from falls from height.

The solutions chosen, whether collective or individual, must protect the team members while they work.

2. In the case of an incident, the company must be prepared with rescue systems for accessing, releasing and evacuating the victim.

These solutions are established with:

- ready-to-use rescue kits, adaptable to many situations and simple to use

- personal equipment for the worker at height (solution requiring experienced and well-trained teams)

In both cases, the teams undergo regular training so they can respond quickly in case of an accident.

Technical rescue

Technical rescue teams must be able to respond quickly in any

situation. They must choose the quickest, most effective way to access the victim.

- When access is easy or possible by motorized means, they can easily transport the rescue equipment

- In more difficult access situations, they may use rope access

techniques, from above or below. They thus have lightweight,

versatile equipment

- Finally, the helicopter can be a means that is used when victim

access is complicated and/or remote, for example in the mountains

Ski lift evacuation

Ski lift evacuation operations follow an evacuation plan. Rescue

kits are put together to meet the specific needs of each ski

center.

1. Accessing the victim

Accessing the victim can sometimes be complicated. Rope access techniques are used in such a case. When access is possible from above, rescuers use rope descent techniques. If an access rope is in place, rescuers can ascend the rope using ventral rope clamp techniques. In other situations, rescuers are obliged to use climbing techniques to reach the victim.

2. Releasing the victim Raising

This involves using a mechanical advantage pulley system in order to easily raise the victim. A rescuer working alone uses a mechanical advantage system to reduce effort. The disadvantage is that a long rope is required. If there are enough rescuers, a lower mechanical advantage is used to speed up the operation.

Counterbalance technique

This is a counterweight system. The rescuer is on one side, the victim on the other. The rescuer unweights the rope on the victim's side by pulling upward. The victim ascends and the rescuer descends. The advantage of this system is that it is easy to do with little equipment. Engaging the counterweight is the step

that demands the most energy. After that, it is important to be careful to keep the system under control. Be careful when there is a significant weight difference between the rescuer and the victim.

3. Evacuating the victim

Downward, the evacuation is done with a descender. This is the easiest technique currently in use. When downward evacuation is impossible, the victim is evacuated upward or horizontally. Upward, rescuers use either a counterweight or hauling technique. Horizontally, one or more ropes are tensioned. One rope is used for carriage, another is used as a back-up belay, and another to move the litter.

EXO AP HOOK

Self-rescue

The typical scenario is of a firefighter trapped inside a burning

structure. S/he needs to be able to ensure his/her own rescue and thus must have the appropriate

equipment.

Technical specifics:

• in this situation, the firefighter must be able to take advantage of any available anchor point inside the building, or as a last resort, a window sill

• the exit generally takes place in an extremely hot, smoke-filled, and hostile environment, adding to the limitations

• the maneuvers must be as simple as possible, for quick action even under intense duress

EXO AP HOOK is a personal escape system with anchor hook

adapted for locations where the possibility of finding an anchor point is uncertain. It has a self-braking system with anti-panic function for quickly moving horizontally, climbing through a window and controlling and stopping a descent. If the user pulls too hard on the handle, the anti-panic function brakes and stops the descent automatically.

JAG RESCUE KIT

The ready-to-use reversible JAG RESCUE KIT is designed to easily unhook and lower a victim. It contains a JAG SYSTEM haul kit, a RING OPEN gated ring, an I’D EVAC descender, a CONNEXION FIXE 150 cm anchor strap, a BUCKET bag and an AXIS 11 mm rope with two sewn terminations.

On-site rescue

If a victim is not able to self-rescue, the on-site work team has to respond immediately and move him/her to safety.

Examples of operations:

• a team member accesses the victim, unhooks him/her, then lowers the victim unaccompanied

• a team member accesses the victim, unhooks him/her, then rappels down with the victim

• the victim is suspended on a pre-installed evacuation system that does not require a team member to access him/her directly

Technical specifics:

• unaccompanied evacuation can generally be done using a ready to- use rescue kit

• accompanied descent requires proper training, as it implies a mastery of advanced rope access techniques

• in all cases, the rescue method should be as rapid as possible, in order to reduce the risk of suspension trauma, especially when the victim is unconscious

Release and rescue using a reversible rescue kit

• Unaccompanied evacuation (when victim doesn't require monitoring or for a free-hanging evacuation):

1. Victim suspended by a lanyard, with the energy absorber torn by the fall.

2. Hauling (allows the victim to be released).

3. Lowering the victim.

STRATO VENT HI-VIZ

Technical rescue

Technical rescue teams respond when the situation is especially difficult and requires significant

resources to be deployed.

Examples of rescues:

• following a vehicle roll-over into a ravine, the victims are rescued via motorized means

• evacuation of an injured worker from a location that is difficult to access

• helicopter rescue operations in mountainous terrain...

Technical specifics:

• technical rescue teams operate in any terrain. They have complete mastery of all progression and belay techniques on rope

• when the terrain allows, downward evacuation is preferred because of the gravity-assist

• upward evacuation is a team effort that requires perfect coordination by everyone involved. It demands techniques which are sometimes particularly complex: raising systems, creating a hauling system using lightweight pulleys, counterweight techniques...

The STRATO VENT HI-VIZ helmet is very lightweight and comfortable, thanks to its CENTERFIT and FLIP&FIT systems,

which guarantee that the helmet fits securely on the head.

It has ventilation holes that allow airflow through the helmet.

The high visibility version features a fluorescent outer shell with phosphorescent clips and reflective bands, for optimal visibility of the worker, day or night.

Technical rescue

Upward and horizontal evacuation in a confined space

1. Raising the NEST litter by a rescuer in counterbalance on rope clamps. A rescuer controls the raise. A third person gives a back-up belay with a second rope.

2. The rescuer below gives slack with a descender. The back-up belayer hauls the NEST litter, allowing it to tilt to a horizontal position with the help of the STEF tilting device.

3. Recovery of the NEST by team members.

Upward and horizontal evacuation by simultaneous traction on two lines

The ropes are used as both work and safety rope.

AUTO LOCK

The AUTO-LOCK system locks the load automatically and returns the handle to the stop position.

Once locked, the rope can be taken up without having to manipulate the handle.

I’D EVAC

Ski lift evacuation

If ski lift equipment fails, the person in charge must evacuate passengers according to the evacuation plan. This evacuation must be done within a predefined time frame, and is generally conducted by the operations staff.

Technical specifics:

• accessing the passengers is done by moving along the cable, from the towers

• these operations are managed

simultaneously by multiple autonomous teams, generally

composed of:

- a person suspended on the cable who evacuates passengers and whose movements are protected by a team member on the tower

- a person on the ground who receives passengers and guides

the movement of the team member on the cable

• the success of these operations

hinges largely on the instruction,

training and practice of the

operations staff (at least once

a year)

The I’D EVAC self-braking descender is designed for lowering from an anchor. The ergonomic handle is specifically oriented for managing a load from the anchor and offers comfortable descent control. The integrated anti-panic unction and anti-error catch limit the risk of an accident due to user error. The AUTO-LOCK system allows the rope to be automatically locked without having to manipulate the handle or tie off the device. The closed auxiliary brake increases the friction as required for the load weight and the rope diameter and provides a constant redirect of the rope.

Ski lift evacuation

Ski lift evacuation with rescuer on cable

Techniques for evacuation from a ski lift differ significantly from one situation to another. A technique is chosen based on the slope of the cable, the clearance above, the distances between pylons, the number of passengers to evacuate, the recovery zone...

To be completed properly and on time, this operation requires training.

1. Rescuer accessing the chair

Back-up belay may be done from the pylon. This allows for a mutual verification of the system before the rescuer moves onto the cable. The rescuer is suspended on the ROLLCAB, and the GRILLON lanyard is slightly slack to allow descent along the cable.

Detail of products making up the rescue kit:

- BERMUDE

- I’D EVAC

- CONNEXION VARIO

- ROLLCAB

- SWIVEL OPEN

- PAW S

- JANE

- GRILLON

- MGO OPEN

- GO x 4

- Am’D x 4

- CAPTIV x 3

- AXIS 11 mm with sewn termination

2. Evacuating the passenger

The rescuer descends on the GRILLON lanyard to the chair. S/he installs the BERMUDE rescue triangle on the victim, then evacuates the victim with an I’D EVAC descender.

Self-locking buckles

These buckles do not require re-threading to be locked: they adjust easily in seconds.

Harnesses

To give each user the best possible fit, Petzl harnesses are adjustable at the waist, shoulders and leg loops. They are equipped with different types of buckles:

Automatic buckles

Automatic buckles open and close simply and quickly, even when wearing gloves, without loss of adjustment.

General purpose harnesses

Fall arrest harnesses

Fall arrest harnesses with a simple,

lightweight design.

Fall arrest and work positioning harnesses

Fall arrest and work positioning harnesses

that are comfortable and easily donned.

Harnesses for fall arrest, work positioning and suspension

Versatile and very comfortable harnesses

for fall arrest, work positioning and suspension.

Rope access harnesses

Very comfortable harnesses,

with integrated ventral rope clamp

to facilitate ascending a rope.

Tree care harnesses

Very comfortable harnesses,

with attachment bridge for greater

freedom of movement in the trees

Rescue harnesses

Lightweight harnesses suitable

for various rescue environments.

Litter and evacuation triangles

Equipment designed for rope rescue

(confined space, ski lifts...).

Specialized harnesses

Fall arrest harnesses

• Great simplicity

NEWTON harnesses have color-coded straps (yellow/black) that allow rapid identification of the upper and lower parts of the harness before donning.

• Quick donning

The NEWTON EASYFIT harness is quickdonning,

thanks to a vest that helps keep its shape. It is equipped with FAST automatic buckles on the leg loops, allowing the harness to be easily donned with both feet on the ground.

• For high visibility

The NEWTON EASYFIT HI-VIZ harness has a fluorescent-colored vest with reflective strips,

making the worker highly visible. It makes the worker more visible on a worksite, road or industrial site regardless of the lighting conditions.

Fall arrest harnesses

The NEWTON fall arrest harness is comfortable for work and easy to use. It is certified to European and Russian standards.

NEWTON European version

Fall arrest harnesses

The NEWTON fall arrest harness is comfortable for work and easy to use. It offers ergonomic stowage of MGO connectors and has fall indicators. It is certified to North American, European and Russian standards.

NEWTON International version

Easy-to-don fall arrest harness

The NEWTON EASYFIT fall arrest harness is easily donned thanks to its EASYFIT design: a vest ensures the harness keeps its shape and the FAST automatic buckles (sternal and leg loop) allow the harness to be donned with both feet on the ground. It is certified to European and Russian standards.

NEWTON EASYFIT European version

Easy-to-don fall arrest harness

The NEWTON EASYFIT fall arrest harness is easily donned thanks to its EASYFIT design: a vest ensures the harness keeps its shape and the FAST automatic buckles (sternal and leg loop) allow the harness to be donned with both feet on the ground. It offers ergonomic stowage of MGO connectors and has fall indicators. It is certified to North American, European and Russian standards.

NEWTON EASYFIT International version

Fall arrest harness with high-visibility vest that is easy to don

The NEWTON EASYFIT HI-VIZ fall arrest harness has a fluorescent-colored vest with reflective strips, making the worker highly visible. It is easily donned thanks to its EASYFIT design. A vest ensures the harness keeps its shape, and the FAST automatic buckles (sternal and leg loop) allow the harness to be donned with both feet on the ground. It offers ergonomic stowage of MGO connectors and hasfall indicators. It is certified to North American, European and Russian standards.

NEWTON EASYFIT HI-VIZ

• For work on towers and antennas

The VOLT and VOLT LT harnesses have a wide waistbelt with equipment loops on the back for easy organization of work tools

Fall arrest and work positioning harnesses

• For work inside wind turbine towers

The VOLT WIND and VOLT WIND LT harnesses have dorsal wear protectors, to reduce wear on the straps when moving about inside a wind turbine tower.

Fall arrest and work positioning harness with attachment point for vertical progression on rail or cable

The VOLT fall arrest and work positioning harness is very easily donned, thanks to its EASYFIT design: a vest ensures the harness keeps its shape, and the FAST automatic buckles on the waistbelt and leg loops allow the harness to be donned with both feet on the ground. The VOLT harness' anatomical design and wide, semi-rigid waistbelt ensure comfort throughout the workday. Its LADDER CLIMB attachment point allows for ventral attachment of the fall-arrest trolley, thus ensuring optimal comfort during progression. It is certified to European and Russian standards (also available in a model certified to European and Canadian standards; comes with OXAN connector).

VOLT®

Fall arrest and work positioning harnesses

The VOLT LT fall arrest and work positioning harness is very easily donned thanks to its EASYFIT design: a vest ensures the harness keeps its shape and the FAST automatic buckles on the waistbelt and leg loops allow the harness to be donned with both feet on the ground. The VOLT LT harness' anatomical design and wide, semi-rigid waistbelt ensure comfort throughout the workday. It is certified to North American and European standards.

VOLT® LT

Fall arrest and work positioning harness for the wind power industry with attachment point for vertical progression on rail or cable

The VOLT WIND fall arrest and work positioning harness is very easily donned thanks to its EASYFIT design: a vest ensures the harness keeps its shape and the FAST automatic buckles on the waistbelt and leg loops allow the harness to be donned with both feet on the ground. The VOLT WIND harness' anatomical design and wide, semi-rigid waistbelt ensure comfort throughout the workday. Its LADDER CLIMB attachment point allows for ventral attachment of the fall-arrest trolley, thus ensuring optimal comfort during progression. It has wear protectors on the waistbelt and below the dorsal point to limit wear when moving about inside the wind turbine tower. It is certified to European and Russian standards (also available in a model certified to European and Canadian standards; comes with OXAN connector).

VOLT® WIND

Fall arrest and work positioning harness for the wind power industry

The VOLT WIND LT fall arrest and work positioning harness is very easily donned, thanks to its EASYFIT design: a vest ensures the harness keeps its shape, and the FAST automatic buckles on the waistbelt and leg loops allow the harness to be donned with both feet on the ground. The VOLT WIND LT harness' anatomical design and wide, semi-rigid waistbelt ensure comfort throughout the workday. It has wear protectors on the waistbelt and below the dorsal point to limit wear when moving about inside the wind turbine tower. VOLT WIND LT is certified to North American and European standards.

VOLT® WIND LT

Seat for VOLT and VOLT LT harnesses for more comfort in suspension

The seat for VOLT harnesses installs in the two side slots of the harness, for increased comfortduring prolonged suspension

Seat for VOLT® harnesses

• A complete solution, with dorsal attachment point

The AVAO BOD and AVAO BOD FAST fullbody

harnesses are equipped with a dorsal attachment point for attaching a fall arrest

system. In case of a fall on this attachment point, a shortened adjustment of the waistbelt to leg loop length means the load is taken up on the leg loops, allowing the user to remain suspended longer while awaiting rescue.

Harnesses for fall arrest, work positioning and suspension

• A lightweight and flexible solution

Combining a seat harness with a separate chest harness is a more lightweight solution, if the user does not need a dorsal attachment point. It is also a solution for hard-to-fit body types, as it allows combining different seat and chest harness sizes.

Comfortable harness for fall arrest, work positioning and suspension

The AVAO BOD fall arrest, work positioning and suspension harness is designed for greater comfort in all situations. Wide, semi-rigid waistbelt and leg loops give excellent support. Its lightweight, breathable construction maximizes air flow. The shoulder straps have a system for stowing the fall arrest lanyard connectors and keeping them within reach. The DOUBLEBACK self-locking buckles at the rear of the harness, between the waistbelt and the leg loops, allow for a shorter adjustment when the dorsal attachment point is used. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders and TOOLBAG tool-holder pouches. The harness is fastened by a SCREW-LOCK manual locking

carabiner and is certified to European and Russian standards. AVAO BOD features leg loops with DOUBLEBACK self-locking buckles; AVAO BOD FAST has leg loops with FAST LT automatic buckles.

AVAO® BOD / AVAO® BOD FAST European version

Chest harness for seat harness

The TOP chest harness transforms AVAO SIT, AVAO SIT FAST, FALCON, FALCON MOUNTAIN

and SEQUOIA SRT seat harnesses into fall arrest harnesses. The foam shoulder straps are widely spaced to reduce neck chafing. When the waistbelt is loaded, they help distribute the load over the shoulders. They also have a system for stowing the fall-arrest lanyard connectors and keeping them within reach.

TOP

Comfortable harness for fall arrest, work positioning and suspension

The AVAO BOD fall arrest, work positioning and suspension harness is designed for greater comfort in all situations. Wide, semi-rigid waistbelt and leg loops give excellent support. Its lightweight, breathable construction maximizes air flow. The shoulder straps have a system for stowing the fall arrest lanyard connectors and keeping them within reach. The DOUBLEBACK self-locking buckles at the rear of the harness, between the waistbelt and the leg loops, allow for a shorter adjustment when the dorsal attachment point is used. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders and TOOLBAG tool-holder pouches. The harness has an integrated fall indicator on the dorsal

attachment point and is fastened with a TRIACT-LOCK automatic locking carabiner. It is certified to North American and European standards. AVAO BOD features leg loops with DOUBLEBACK self-locking buckles; AVAO BOD FAST has leg loops with FAST automatic buckles.

AVAO® BOD / AVAO® BOD FAST international version

Comfortable seat harness for work positioning and suspension

The AVAO SIT work positioning and suspension seat harness is designed for greater comfort in a variety of situations. Wide, semi-rigid waistbelt and leg loops give excellent support. Its lightweight, breathable construction maximizes air flow. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders and TOOLBAG tool-holder pouches. This seat harness is designed to be converted into a fall arrest harness when combined with a TOP chest harness, or into a rope access harness when combined with a TOP CROLL S or L chest harness. The AVAO SIT has leg loops with DOUBLEBACK self-locking buckles; AVAO SIT FAST leg loops have FAST automatic buckles.

AVAO® SIT / AVAO® SIT FAST

• A complete solution, with dorsal attachment point

ASTRO BOD FAST full-body harnesses are equipped with a dorsal attachment point for

attaching a fall arrest system. In case of a fall

on this attachment point, a shortened adjustment of the waistbelt to leg loop length means the load is taken up on the leg loops, allowing the user to remain suspended longer while awaiting rescue.

Rope access harnesses

• A lightweight and flexible solution

Combining a seat harness with a separate

chest harness is a more lightweight solution,

if the user does not need a dorsal attachment point. It is also a solution for hard-to-fit body types, as it allows combining different seat and chest harness sizes

Ultra-comfortable rope access harness

With an integrated CROLL L ventral rope clamp, the ASTRO BOD FAST harness is designed for greater efficiency and comfort during rope ascents. The gated ventral attachment point allows optimal integration of equipment (rope clamp, lanyard, seat...). Wide, semi-rigid waistbelt and leg loops give excellent support. They are contoured and lined with breathable foam padding for comfort when suspended. The DOUBLEBACK self-locking buckles at the rear of the harness, between the waistbelt and the leg loops, allow for a shorter adjustment when the dorsal attachment point is used. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders and TOOLBAG tool-holder pouches. It is certified to European and Russian standards. The ASTRO BOD FAST European version features leg loops with FAST LT automatic buckles.

ASTRO® BOD FAST European version

Ultra-comfortable rope access harness

With an integrated CROLL L ventral rope clamp, the ASTRO BOD FAST harness is designed for greater efficiency and comfort during rope ascents. The gated ventral attachment point allows optimal integration of equipment (rope clamp, seat...). Wide, semi-rigid waistbelt and leg loops give excellent support. They are contoured and lined with breathable foam padding for comfort when suspended. The DOUBLEBACK self-locking buckles at the rear of the harness, between the waistbelt and the leg loops, allow for a shorter adjustment when the dorsal attachment point is used. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders and TOOLBAG tool-holder pouches. It has a fall indicator on the dorsal attachment point and is certified to North American and European standards. ASTRO BOD FAST international version features leg loops with FAST automatic buckles.

ASTRO® BOD FAST European version

Chest harness for seat harness, with integrated CROLL S ventral rope clamp

The TOP CROLL S integrates a CROLL S ventral rope clamp to transform ASTRO SIT FAST, AVAO SIT, AVAO SIT FAST, FALCON and FALCON ASCENT harnesses into rope access harnesses. The textile sternal attachment point optimally reduces weight and bulk. The foam shoulder straps are widely spaced to reduce neck chafing. When the waistbelt is loaded, they help distribute the load over the shoulders. The rear connection, on each side of the waistbelt, offers excellent stability.

TOP CROLL® S

Chest harness for seat harness, with integrated CROLL L ventral rope clamp

The TOP CROLL L integrates a CROLL L ventral rope clamp to transform ASTRO SIT FAST, AVAO SIT,AVAO SIT FAST, FALCON, FALCON ASCENT and SEQUOIA SRT harnesses into rope access harnesses. The foam shoulder straps are widely spaced to reduce neck chafing. When the waistbelt is loaded, they help distribute the load over the shoulders.

TOP CROLL® L

Ultra-comfortable rope access seat harness

The ASTRO SIT FAST rope access seat harness features a gated ventral attachment point that allows optimal integration of equipment (rope clamp, lanyard, seat...). Wide, semi-rigid waistbelt and leg loops give excellent support. They are contoured and lined with breathable foam padding for comfort when suspended. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders and TOOLBAG tool-holder pouches. This seat harness is designed to be converted into a full body harness when combined with a TOP CROLL S or L chest harness. The ASTRO SIT FAST features leg loops with FAST LT automatic buckles.

ASTRO® SIT FAST

Seat for prolonged suspension

The PODIUM provides optimal comfort during prolonged suspension. The wide seat offers excellent stability. Rigid sides prevent the webbing straps from cutting into the thighs. The easy-to-use seat has two equipment loops and a rear hook, making it easier to store in order to facilitate movement. It connects to ASTRO BOD FAST and ASTRO SIT FAST harnesses with two shackles (find a description of the shackles on page 63).

PODIUM

• For single rope ascent techniques

The SEQUOIA SRT features a ventral attachment point for installing a ZIGZAG mechanical Prusik with the CHICANE and KNEE ASCENT accessories.

Tree care harnesses

• For doubled rope ascent techniques

The SEQUOIA harness waistbelt is equipped

with a FAST automatic buckle for quick and

simple opening and closing, without loss of

adjustment, even while wearing gloves.

Tree care seat harness for single rope ascent techniques

The SEQUOIA SRT is a tree care seat harness for ascents on a single rope. It has a ventral attachment point that allows a ZIGZAG or ZIGZAG PLUS mechanical Prusik to be installed with the CHICANE and KNEE ASCENT accessories. The extra-wide, semi-rigid waistbelt and leg loops provide comfort for the arborist. It is equipped with DOUBLEBACK PLUS self-locking buckles on the waistbelt and FAST LT PLUS automatic buckles on the leg loops. The gated attachment points allow the user to easily connect a ZILLON or MICROFLIP lanyard,

or to install several attachment bridges and accessories directly on the bridge. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders.

SEQUOIA SRT

Tree care seat harness for doubled-rope ascent techniques

The SEQUOIA is a tree care seat harness for doubled-rope ascent techniques. The extra-wide, semi-rigid waistbelt and leg loops provide comfort for the arborist. The waistbelt is equipped with a FAST automatic buckle for quick and simple opening and closing, without loss of adjustment, even while wearing gloves. The leg loops have FAST LT PLUS automatic buckles. The gated attachment points allow the user to easily connect a ZILLON or MICROFLIP lanyard, or to install several attachment bridges and accessories directly on the bridge. The harness also facilitates the carrying and organizing of work tools, with multiple equipment loops and retainers for attaching CARITOOL tool holders.

SEQUOIA

Shoulder straps (only for SEQUOIA SRT)

Shoulder straps for SEQUOIA SRT seat harness designed for taking the load from the waistbelt and redistributing it to the shoulders for improved comfort. They connect to the ventral attachment point of the harness and to the two slots at the rear of the waistbelt.

Seat

Wide seat for a comfortable working position during suspension. It has an adjustable width to reduce bulk and facilitate movement within the tree. It connects to the two gated points on the SEQUOIA and SEQUOIA SRT arborist seat harnesses, using the two shackles.

Adjustable attachment bridge

Adjustable attachment bridge for SEQUOIA and SEQUOIA SRT harnesses allows quick and precise adjustment of the position of progression tools installed on the bridge.

Attachment bridge

Attachment bridge for connection to the two gated attachment points of the SEQUOIA and SEQUOIA SRT arborist seat harnesses, to optimize lateral mobility.

RING

The RING connection ring can be used to create multiple anchors or be installed directly onto the SEQUOIA and SEQUOIA SRT harnesses' attachment bridges to improve the arborist's lateral mobility.

Shackles

Shackles for connecting a seat. Find a description of the shackles on page 63.

• For work in suspension

The metal ventral attachment point on the FALCON harness distributes the load between the waistbelt and the leg loops during suspension.

Rescue harnesses

• For efficiency when ascending a rope

The two-part ventral attachment point of the FALCON ASCENT harness increases the efficiency of rope ascents when using a CROLL ventral rope clamp.

• For operations using climbing techniques

The textile bridge construction of the FALCON MOUNTAIN harness favours progression with climbing techniques and makes for comfortable walking.

Lightweight seat harness for suspended rescue

FALCON is a lightweight seat harness with a metal ventral attachment point that distributes the load between the waistbelt and the leg loops during suspended rescue. It has a waistbelt and leg loops that are semi-rigid for comfort and equipped with self-locking DOUBLEBACK buckles for quick and easy adjustment. The rear buckle allows a TOP or TOP CROLL chest harness to be installed.

FALCON

Lightweight seat harness for rescue operations involving rope ascent

FALCON ASCENT is a lightweight seat harness featuring a two-part ventral attachment point that fastens with an OMNI carabiner. This attachment point makes it more efficient during rescue operations involving rope ascent. The FALCON ASCENT harness features a semi-rigid waistbelt and leg loops for maximum comfort and self-locking DOUBLEBACK buckles for quick and easy adjustment. The rear buckle allows a TOP CROLL chest harness to be installed.

FALCON ASCENT

Very lightweight seat harness for rescue operations involving technical climbing

FALCON MOUNTAIN is a very lightweight seat harness for rescue operations involving technical climbing. It features a bridge construction that favorus progression with climbing techniques and makes it comfortable when walking. It has a waistbelt and leg loops that are semi-rigid for comfort and equipped with self-locking DOUBLEBACK buckles for quick and easy adjustment. The rear buckle allows a TOP chest harness to be installed.

FALCON MOUNTAIN

Chest harness for seat harnesses

The CHEST’AIR chest harness transforms FALCON, FALCON MOUNTAIN, AVAO SIT and SEQUOIA SRT seat harnesses into fall arrest harnesses. Connects simply to the harness ventral attachment point for rapid installation. It adapts easily to all body types with its DOUBLEBACK self-locking buckles on the shoulder straps and ventral strap.

CHEST’AIR

Litter for confined spaces

The NEST litter was developed in partnership with the French national caving rescue organization. It allows a victim to be transported horizontally, vertically or at an angle. It is therefore suitable for all technical rope rescue, particularly in confined spaces.

NEST

Litter and evacuation triangles

Rescue litter

Evacuation triangles

Tilting device for NEST litter

The STEF device joins the three connection points of the NEST litter and allows it to be easily tilted according to the terrain.

STEF

Bag for NEST litter

Evacuation triangle with shoulder straps

The PITAGOR is an evacuation triangle with shoulder straps that are easily donned and adjusted thanks to the DOUBLEBACK self-locking buckles.

PITAGOR

Evacuation triangle without shoulder straps

The BERMUDE is an evacuation triangle without shoulder straps that is easily put on and adapts without adjustment to different sizes.

BERMUDE

Spreader for NEWTON harness (European version)

Spreader for NEWTON harness (European version) allows upright descent (for confined spaces).

LIFT

Harness accessories

Harness tool holder

The CARITOOL tool holder provides one-handed tool access and storage. It slips onto the harness straps and stays in place, thanks to its stabilizing clip. The gate has a protective feature that limits accidental snagging. It is available in two sizes.

CARITOOL

Tool pouch

The TOOLBAG tool pouch allows the user to organize his/her tools during suspended work. The cord lock allows the pouch to be closed easily during transport or when moving about. The pouch attaches easily to any type of harness. Available in three sizes: XS, S and L.

TOOLBAG

Multidirectional gated ring

See page 102 for details on the RING OPEN gated ring

RING OPEN

Shackles for connecting a seat.

Connection to the gated ventral attachment point of the harnesses ensures optimal integration of equipment.

Shackles

General purpose harnesses

Specialized harnesses

Helmets

Comfortable helmets

Helmets with webbing suspension for optimal comfort.

Lightweight helmets

Lightweight, compact helmet with hybrid construction liner (EPP and EPS foams).

Protective eye and face shields

Protective eye and face shields for VERTEX and STRATO helmets.

Hats and balaclava

Hats and balaclava for protection against rain and cold.

Helmets

• Comfortable construction

VERTEX helmets have a six-point webbing suspension system, conforming to the shape of the head for maximum comfort. Shock absorption is achieved through deformation of the external shell

Helmets

• Lightweight construction

The liner of STRATO helmets is designed in two parts: EPP (expanded polypropylene) and EPS (expanded polystyrene), for reduced weight. Shock absorption is achieved through deformation of the liner.

Comfortable helmet

The VERTEX helmet is very comfortable, thanks to its six-point textile suspension and CENTERFIT and FLIP&FIT systems, which guarantee that the helmet fits securely on the head. The adjustable-strength chinstrap makes it ideal for both work at height and on the ground. The unventilated outer shell protects against electrical hazards, molten metal splash and flames. With its potential for integration of a Petzl headlamp, hearing protection, and multiple accessories, it is an entirely modular helmet, thus meeting the specific additional needs of professionals.

VERTEX®

Comfortable high-visibility helmet

The high visibility version features a fluorescent outer shell with phosphorescent clips and reflective bands, for optimal visibility of the worker, day or night.

VERTEX® HI-VIZ

Comfortable ventilated helmet

The VERTEX VENT helmet is very comfortable, thanks to its six-point textile suspension and CENTERFIT

and FLIP&FIT systems, which guarantee that the helmet fits securely on the head. The adjustable-strength chinstrap makes it ideal for both work at height and on the ground. It has ventilation holes with sliding shutters to allow airflow through the helmet. With its potential for integration of a Petzl headlamp, hearing protection, and multiple accessories, it is an entirely modular helmet, thus meeting the specific additional needs of professionals.

VERTEX® VENT

Comfortable, ventilated high-visibility helmet

The high visibility version features a fluorescent outer shell with phosphorescent clips and reflective bands, for optimal visibility of the worker, day or night.

VERTEX® VENT HI-VIZ

Lightweight helmet

The STRATO helmet is very lightweight and comfortable, thanks to its CENTERFIT and FLIP&FIT systems, which guarantee that the helmet fits securely on the head. The adjustable-strength chinstrap makes it ideal for both work at height and on the ground. The unventilated outer shell protects against electrical hazards, molten metal splash and flames. With its potential for integration of a Petzl headlamp, hearing protection, and multiple accessories, it is an entirely modular helmet, thus meeting the specific additional needs of professionals.

STRATO

Lightweight high-visibility helmet

The high visibility version features a fluorescent outer shell with phosphorescent clips and reflective bands, for optimal visibility of the worker, day or night.

STRATO HI-VIZ

Lightweight ventilated helmet

The STRATO VENT helmet is very lightweight and comfortable, thanks to its CENTERFIT and FLIP&FIT

systems, which guarantee that the helmet fits securely on the head. The adjustable-strength chinstrap

makes it ideal for both work at height and on the ground. It has ventilation holes that allow airflow

through the helmet. With its potential for integration of a Petzl headlamp, hearing protection, and multiple accessories, it is an entirely modular helmet, thus meeting the specific additional needs of professionals.

STRATO VENT

Lightweight, ventilated high-visibility helmet

The high visibility version features a fluorescent outer shell with phosphorescent clips and reflective bands, for optimal visibility of the worker, day or night.

STRATO VENT HI-VIZ

Eye shield with EASYCLIP system for VERTEX and STRATO helmets

The VIZIR eye shield protects the eyes against projectile hazards. It is easy to install on VERTEX and STRATO helmets with the EASYCLIP attachment system. It also has scratch-resistant and anti-fog coatings.

VIZIR

Helmets

Protective eye and face shields

Tinted eye shield with EASYCLIP system for VERTEX and STRATO helmets

The VIZIR SHADOW eye shield provides eye protection against projectile hazards. It is easy to install on VERTEX and STRATO helmets with the EASYCLIP attachment system. It has a level 2.5 solar protection filter, and anti-scratch and anti-fog treatments.

VIZIR SHADOW

The protector for VIZIR and VIZIR SHADOW protects the eye shields from scratches. It is installed directly on the VIZIR and VIZIR SHADOW eye shields. It allows a Petzl headlamp to be worn, thanks to a mounting slot on the protector.

Protector for VIZIR and VIZIR SHADOW

Face shield for protection against electric arc hazards, with EASYCLIP system for VERTEX and STRATO helmets

The VIZEN face shield protects against electric arc hazards. This full-coverage shield offers face and eye protection while preserving peripheral vision. It is easily installed on VERTEX and STRATO helmets, thanks to the EASYCLIP attachment system. It also has scratch-resistant and anti-fog coatings.

VIZEN

Face shield for tree care for VERTEX and STRATO helmets, with EASYCLIP system

The VIZEN MESH face shield protects against flying wood chips and shavings. This full-coverage shield offers complete face protection while ensuring good visibility. It is easily installed on VERTEX and STRATO helmets, thanks to the EASYCLIP attachment system.

VIZEN MESH

Mounting clips allow a Bollé welding mask to be installed.

Mounting clips for welding mask

Mounting clip allows a Bollé welding face shield to be installed.

Mounting clip for welding face shield

The nametag holder for VERTEX and STRATO helmets allows quick identification of the worker. It is easy to install and provides effective rain protection for business cards.

Nametag holder for VERTEX® and STRATO helmets

Accessories

The nape protector for VERTEX and STRATO helmets provides effective sun and rain protection for the nape of the neck. Fluorescent colors give the worker optimal visibility, night and day. Available in two colors.

Nape protector for VERTEX® and STRATO helmets

The protector for the VERTEX helmet is easy to install and protects the shell from soiling and splash.

Protector for VERTEX® helmet

The protector for the STRATO helmet is easy to install and protects the shell from soiling and splash.

Protector for STRATO helmet

Storage bag to protect VERTEX and STRATO helmets during storage and transport. Thanks to a closed interior compartment, accessories are also protected.

Storage bag for VERTEX® and STRATO helmets

This chinstrap allows the chinstrap of VERTEX and STRATO helmets to be changed or replaced. It allows the worker to modify chinstrap strength in order to adapt the helmet to different environments: work at height or on the ground. Available in two colors and in a longer version.

DUAL chinstrap for VERTEX® and STRATO helmets

Headband with comfort foam for VERTEX and STRATO helmets (pack of 5)

Ready to install headband with comfort foam (standard or absorbent), to extend the life of a VERTEX or STRATO helmet

Headband with comfort foam for VERTEX® and STRATO helmets

Helmets

Accessories

Comfort foam (standard or absorbent), ready to install on headband of a VERTEX or STRATO helmet, to prolong its life.

Comfort foam for VERTEX® and STRATO helmets

Upper foam installs on the liner of the STRATO helmet, to extend its life. It is comfortable, absorbent and machine-washable

Upper foam for STRATO helmet

Transparent stickers allow VERTEX and STRATO helmets to be personalized using a permanent marker or laser printer

Transparent stickers for VERTEX® and STRATO helmets

Reflective stickers for increased visibility of VERTEX helmets.

Reflective stickers for VERTEX®

Reflective stickers for increased visibility of STRATO helmets.

Reflective stickers for STRATO

Breathable cap for wicking perspiration

LINER is a breathable cap for wicking perspiration and drying quickly. The seamless fitted design makes it comfortable to wear under a helmet, without getting in the way

LINER

Protective cap for cold and wind

BEANIE is a cap that protects the head on cold and windy days. The design, specific to each zone, optimizes thermal insulation and regulates moisture. The seamless fitted design and side vents make it comfortable to wear under a helmet, without getting in the way.

BEANIE

Balaclava for protection against cold and wind

BALACLAVA protects the head, the face and the neck on cold, windy days. The design, specific to each one, optimizes thermal insulation and regulates moisture. The seamless fitted design and multiple side vents make it comfortable to wear under a helmet, without getting in the way.

BALACLAVA

Helmets

Lanyards and energy absorbers

Work positioning lanyards

Adjustable lanyards used to make work positioning systems, to complement a fall-arrest system. Their length can be very easily and precisely adjusted as necessary for comfortable positioning at a specific work station.

General purpose lanyards

Fall arrest lanyards

Lanyards with an energy absorber, used when there is a fall hazard. Petzl offers three types of lanyards with an absorber:

- single (ABSORBICA-I) or double (ABSORBICA-Y) lanyards with a compact, integrated energy absorber. In case of a fall, the absorber's progressive tearing reduces the deceleration on lightweight users

- lanyards that can be combined with an ABSORBICA energy absorber to create a single or double energy-absorbing lanyard with a maximum length of two meters

Rope access lanyards

Fixed-length or adjustable progression lanyards, available in single or double versions.

Specialized lanyards

Tree care lanyards

Adjustable positioning lanyards that allow comfortable positioning for tree care work.

Helivac lanyards

Lanyards for helicopter drop-off and recovery.

• Work positioning lanyards

GRILLON lanyards are sold without connectors, so that they can be combined with any type of connector, depending on the user's requirements.

Work positioning lanyards

• With MGO connector

GRILLON lanyards, in combination with an MGO auto-locking connector, are ideal for connection to metal structures or to large-diameter cables and bars.

• With HOOK connector

GRILLON HOOK lanyards are equipped with a HOOK auto-locking connector, ideal for connections using the harness side attachment points.

Adjustable lanyard for work positioning

The GRILLON adjustable lanyard is used to make work positioning systems, to complement a fall-arrest system. Its length can be very easily and precisely adjusted as necessary for comfortable positioning at the work station. Depending on the configuration, it can be used in single or double mode. GRILLON is available in seven lengths (2, 3, 4, 5, 10, 15 and 20 m), and also in black. It is certified to North American, European and Russian standards.

GRILLON

Adjustable work positioning lanyard with high abrasion resistance

The GRILLON PLUS lanyard is used to make work positioning systems, to complement a fall arrest system. Its length can be very easily and precisely adjusted as necessary for comfortable positioning at the work station. The aramid fiber rope provides excellent abrasion resistance. Depending on the configuration, it can be used in single or double mode. GRILLON PLUS is available in two lengths: 2 and 3 m, and is certified to North American, European and Russian standards.

GRILLON PLUS

Adjustable work positioning lanyard with HOOK connector

The GRILLON HOOK adjustable lanyard is used to make work positioning systems, to complement a fall-arrest system. Its length can be very easily and precisely adjusted as necessary for comfortable positioning at the work station. Its HOOK connector is ideal for using the lanyard in double mode on the harness side attachment points. GRILLON HOOK European version is available in four lengths (2, 3, 4 and 5 m) and is certified to European and Russian standards.

GRILLON HOOK European version

Adjustable work positioning lanyard with HOOK connector

The GRILLON HOOK adjustable lanyard is used to make work positioning systems, to complement a fall-arrest system. Its length can be very easily and precisely adjusted as necessary for comfortable positioning at the work station. Its HOOK connector is ideal for using the lanyard in double mode on the harness side attachment points. GRILLON HOOK international version is available in four lengths (2, 3, 4 and 5 m) and is certified to North American and European standards.

GRILLON HOOK international version

Adjustable lanyard for work positioning

GRILLON

Adjustable work positioning lanyard with MGO connector

The GRILLON MGO lanyard is used to make work positioning systems, to complement a fall arrest system. Its length can be very easily and precisely adjusted as necessary for comfortable positioning at the work station. Connector with large gate opening is ideal for connection to metal structures or to large-diameter cables and bars. GRILLON MGO is available in two lengths: 2 and 3 m, and is certified to North American and European standards.

BALACLAVA

MGO OPEN 60

Auto-locking directional connector with large gate opening, and a gated connection point

See page 101 for details on the MGO OPEN 60 connector.

MGO OPEN 60

• For continuous protection without passage of intermediate anchors

ABSORBICA-I single lanyards are designed

particularly for protection on a horizontal lifeline

or on an elevated platform

Fall arrest lanyards

• For continuous protection when passing intermediate anchors

The ABSORBICA-Y lanyards with two arms

allow for continuous protection when passing

an intermediate anchor, by successively

detaching and re-attaching the two arms

Single lanyard with integrated energy absorber

Single lanyard with a compact, integrated energy absorber designed for protection on a horizontal lifeline (rope or cable) or on an elevated platform. It is available in 80 or 150 cm versions (without connectors). It can accept different types of connectors on the lanyard end and is certified to European and Russian standards

ABSORBICA-I European version

Single lanyard with integrated energy absorber and captive carabiners

Single lanyard with a compact, integrated energy absorber designed for protection on a horizontal lifeline (rope or cable) or on an elevated platform. It is available in 80 or 150 cm versions (without connectors). Equipped with two captive carabiners, it is certified to North American and European standards.

ABSORBICA-I International version

Adjustable single lanyard with integrated energy absorber

Adjustable single lanyard with a compact, integrated energy absorber designed for protection on a horizontal lifeline (rope or cable) or on an elevated platform. This lanyard features the VARIO adjustment system, allowing the lanyard length to be adjusted in order to reduce the potential fall height. ABSORBICA-I VARIO is certified to European and Russian standards.

ABSORBICA-I VARIO

Double lanyard with integrated energy absorber